CNC technology is a product of mechatronics, embodying the combination of computers and machinery. Since the 1950s, CNC technology has gone through five stages, achieved remarkable application results, and accumulated valuable experience, which is of high reference significance.

Manufacturing enterprises recognize the important role of CNC technology in improving product quality and economic development, so promoting the development of digital CNC technology can help to improve China’s manufacturing level.

CNC technology is closely related to computer, communication, mechanical engineering, optoelectronics, and sensing technologies, and is a core component of mechanical manufacturing automation.

1. Current state of development of digital technologies

Facing the challenges of double development of economy and science and technology as well as the competition of great powers, the independent innovation of China’s CNC technology needs to be improved urgently. At the same time, it is crucial to find a development path in line with national conditions, which is the only way to enhance CNC technology research and development and international competitiveness.

Currently, the Chinese state still has deficiencies in developing CNC technology, including data accuracy, quality, and application.

CNC technology also has “three lack of a low” phenomenon: the lack of accurate parameters, the lack of scientific guidance, the lack of a benign platform, and the overall efficiency is low, these problems hinder the development of CNC technology and the manufacturing industry.

To enhance the international status and corporate image, it is necessary to increase the innovation and application of CNC technology.

2. Wide application of numerical control technology

CNC technology to promote the manufacturing industry to automation, and digital development, enhance the level of mechatronics, and the control of CNC machine tools require more.

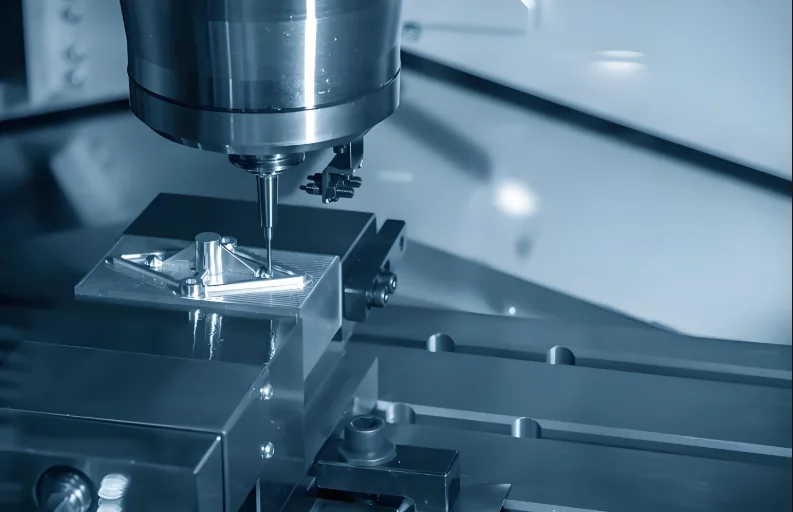

CNC machine tools combine equipment and computers, a product of the information age, which simplifies complex procedures and saves time and labor by transmitting instructions through codes, data, and media.

The application of CNC technology in mold machining, especially CAM software, has become a regular trend, mainly for CNC machining programming and shop floor machining programming.

New software reduces tool-to-tool speeds, improves tool life, and helps with equipment maintenance by incorporating helical machining tools. Good software has clear advantages not only as a tool but also as an innovative means of improving the quality of data processing

3. China’s future development trend of CNC machine tools

Five-axis linkage machine tools can effectively handle complex programs and are particularly suitable for hardcore material operations. Although not yet widely used due to price and technical difficulties, the emergence of electric spindles reduces the cost and difficulty, promotes the development of five-axis linkage and composite machine tools, enhances the economic benefits of enterprises, and promotes the overall level of manufacturing.

Most of China’s machine tools are economic, high-grade CNC machine tools rely on imports, restricting its economy and security. Therefore, the development of self-developed medium- and high-end CNC technology, especially CNC machine tools and large machine tools, is the current top priority.

The choice of materials is crucial to the operation and quality of the equipment, and new environmentally friendly materials should be used to improve the efficiency of CNC technology, reduce costs, save resources, and meet national development needs.

Greatly strengthen the technology and support services. CNC technology belongs to the high-end type of industrial technology, so increasing technology and support services is a necessary link.

In addition to the technical aspects of CNC technology requires a certain amount of hardware, but also needs to have a good reputation as a support, CNC products have technical advantages of the price is also expensive, so the product service must be done to avoid the embarrassing situation of selling no one to manage, which will greatly affect the marketing of the CNC products, therefore, it must be technical support services as a key task to grasp.

Having a strong backbone in the deep market trend ensures that marketing takes place in a safe and stable environment.

4 Conclusion

At present, although China’s development in the CNC industry is relatively slow, and the mechanism and other aspects are not sound, in the world’s developing stage, with the improvement of skills and the application of science and technology, as well as the intervention of scientific management and marketing methods, soon there will be a brand new situation.

At present, the development of the world and the competitiveness between countries rely on science and technology and innovation ability, therefore, taking the road of independent research and development and innovation is an inevitable choice.