New heat treatment technologies, like vacuum heat treatment, revolutionize welding by enhancing mechanical properties and weld durability.

Common methods include induction heating, laser quenching, and vacuum heat treatment. These techniques reduce residual stresses, refine microstructures, and improve corrosion and fatigue resistance. Industries such as automotive, aerospace and high-strength structure manufacturing widely use these methods.

Vacuum Heat Treatment Technology Overview

1.1 Definitions and Principles

Vacuum heat treatment technology heats and cools metals in a vacuum environment to improve their mechanical, physical, and chemical properties. High-temperature heating transforms the material’s internal structure and prevents oxidation and decarburization.

This ensures better purity and surface quality. The low gas density in the vacuum chamber allows precise temperature control and rapid cooling. This improves process stability and product performance.

This technology includes processes such as annealing, quenching, and tempering. It finds extensive use in aerospace, automotive manufacturing, and precision instrument production.

1.2 Strengths and Limitations

Vacuum heat treatment provides several significant advantages. It optimizes the material’s microstructure and increases hardness, strength, and toughness. It prevents oxidation and decarburization.

The process eliminates welding stress, refines grain structure, and increases weld strength and durability. Although the initial investment is high, the technology consumes less energy, produces fewer defects, and lowers long-term costs.

However, vacuum heat treatment has some limitations. It requires high operational costs, involves complex procedures, and needs skilled personnel for maintenance.

Traditional methods may still perform better for large workpieces or specialized materials. The process also takes a long time, which reduces production efficiency. Manufacturers must evaluate material properties, workpiece specifications, and cost factors to choose the best method.

Application Analysis of Vacuum Heat Treatment Technology

2.1 Test Materials and Methods

2.1.1 Test Materials

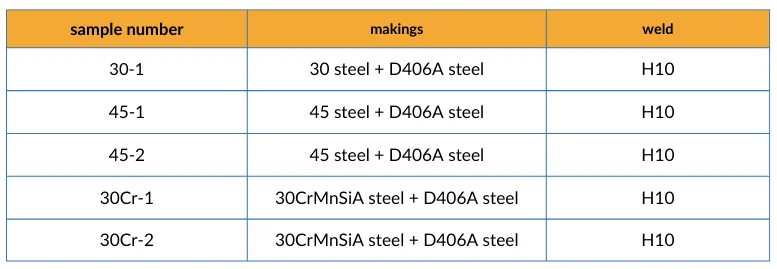

The vacuum heat treatment experiments used 30 steel, 45 steel, and 30CrMnSiA steel. The tests paired these materials with compatible welding wires. Table 1 summarizes the detailed specimen data.

2.1.2 Test Methods

The experiment divided specimens into groups for vacuum air quenching. The groups included welded tensile and flexural samples to assess performance. All specimens went through vacuum heating and gas quenching. The first heating stage raised the temperature to 700°C for 50 minutes.

The temperature then increased to 930°C for 40 minutes. After that, the specimens were cooled with ammonia at 2×10⁴ Pa pressure. The next stage involved vacuum tempering. The specimens were heated to 300°C and held for 90 minutes. Finally, they cooled under 1×10⁴ Pa nitrogen pressure.

The SYD305C material testing machine measured tensile strength. The DY-10 universal testing machine handled bending tests. Optical microscopy analyzed microstructure and fracture morphology to assess mechanical property changes.

2.2 Experimental Results and Analysis

2.2.1 Mechanical Properties

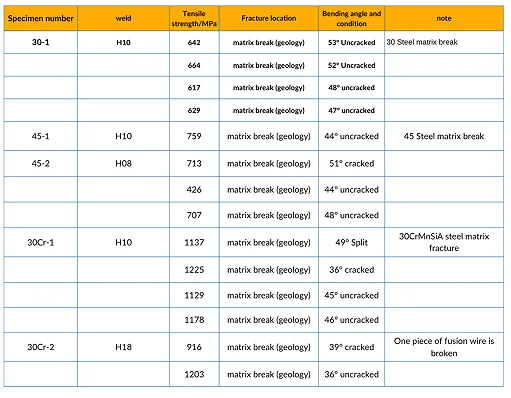

Tensile and bending tests measured mechanical properties. The welded specimens of 30 steel, 45 steel, and 30CrMnSiA steel with D406A steel showed clear differences in performance after vacuum heat treatment with nitrogen quenching at 2×10⁴ Pa. Table 2 presents the results.

The 30 steel and D406A steel welded specimens (30-1) had lower tensile strength, ranging from 617 to 664 MPa. The fractures occurred in the base material. This shows that the weld region had high strength, but the overall performance did not meet design requirements. The 45 steel and D406A steel welded specimens (45-1 and 45-2) had higher tensile strengths of 426-759 MPa. However, they also fractured in the base material, proving that the matrix material still limited strength.

2.2.2 Hardness

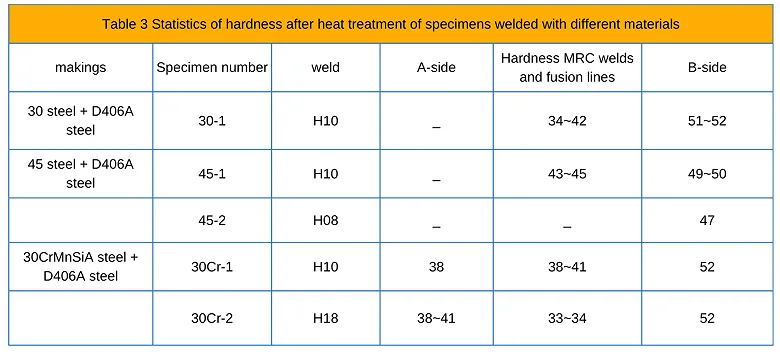

Hardness measurements covered the base, weld, and fusion line regions. The 30, 45, and 30CrMnSiA steel specimens welded to D406A steel showed different hardness patterns after heat treatment. Table 3 provides the details.

2.2.3 Grain Size

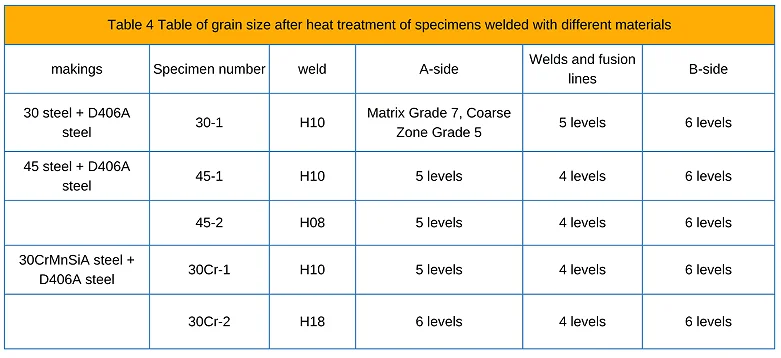

The grain size evaluation included the base, weld, and fusion line areas. The specimens showed varying grain size characteristics after vacuum heat treatment. Table 4 presents the results.

3 Conclusion

In summary, advanced heat treatment technologies improve material performance and weld quality. They provide strong technical support for modern manufacturing advancements.

Future heat treatment technologies will become more intelligent and automated. This will improve process stability and control precision. As environmental regulations grow stricter, researchers will focus on developing eco-friendly heat treatment methods. These innovations will ensure sustainable industrial development.