Additive Manufacturing (AM) in Aircraft Landing Gear: Progress, Advantages, and Challenges

Overview of Additive Manufacturing Technology

Additive Manufacturing (AM) is an advanced production technology that builds components layer by layer from digital models, reshaping traditional subtractive manufacturing methods. Based on heat source types, AM can be categorized into:

Selective Laser Melting (SLM)

Laser Cladding Deposition (LSF)

Wire Arc Additive Manufacturing (WAAM)

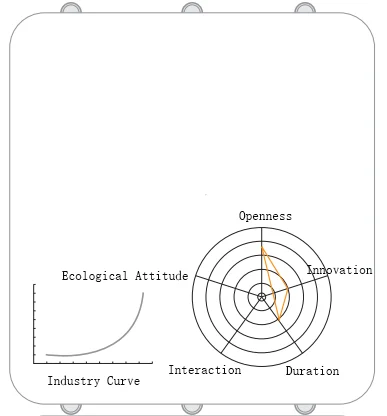

AM integrates CAD modeling, material processing, and precision molding. It enables the creation of parts with high specific strength, complex geometries, shorter production cycles, and enhanced functionality — all without relying on specialized tooling. The technology supports lightweight design, and digital integration, and promotes eco-friendly manufacturing.

2 Development of AM in the Aviation Sector

2.1 Structural Components and Repair Applications

Companies like Lockheed Martin leverage AM to produce titanium alloy secondary load-bearing parts for aircraft, meeting fatigue performance requirements. For example, the F-35 aileron beams manufactured with AM saw a cost reduction of 1/3 to 2/3 compared to traditional methods. Meanwhile, Oak Ridge National Laboratory developed nickel-based high-temperature alloys with performance comparable to forgings.

2.2 Addressing Porosity Issues

Juechter and Meid’s research identified the causes of pores in AM parts. Spherical pores often result from operator errors or improper powder production, preventing gas escape. Non-spherical pores stem from unstable molten pools, insufficient energy, or element evaporation. By optimizing process parameters, these defects can be minimized.

2.3 Improving Performance and Accuracy

Denlinger et al. explored how thermal gradients cause residual stress and deformation. Adjusting power, scanning speed, heat dissipation, and part dimensions significantly reduced warping.

Additionally, Körner and Tammas-Williams studied element evaporation’s effect on mechanical properties, while Baufeld et al. found that slicing errors and step effects compromise surface precision.

3 AM Advancements in Aircraft Landing Gear

3.1 Performance Requirements for Landing Gear

The landing gear is the only component that makes contact with the ground during takeoff and landing, enduring massive impact forces. As a result, materials must exhibit:

High strength

Toughness

Fatigue resistance

Corrosion resistance

They must also adapt to complex environments and temperature extremes.

3.2 Energy Absorption Methods

Modern landing gear designs primarily rely on two energy absorption methods:

Oil-gas energy Absorption: Reduces manufacturing time and lowers weight by approximately 15%.

Structural Deformation Energy Absorption: Shenyang Aircraft Design Institute pioneered using AerMet-100 steel powder in AM to fabricate front landing gear — achieving successful ground and flight tests.

3.3 Deformable Energy-Absorbing Landing Gear

Skid-Type: Built from uniform-thickness round tubes, though its rigid design limits energy absorption.

Leaf Spring-Type: Allows deformation adjustment via secondary processing, but solid design leads to low energy absorption per weight.

Joby Aviation designed and produced a new deformable landing gear using AM, which successfully passed drop impact tests and flight trials — a breakthrough in lightweight, high-performance designs.

4 Key Advantages of AM in Landing Gear Manufacturing

4.1 Complex Geometries Made Simple

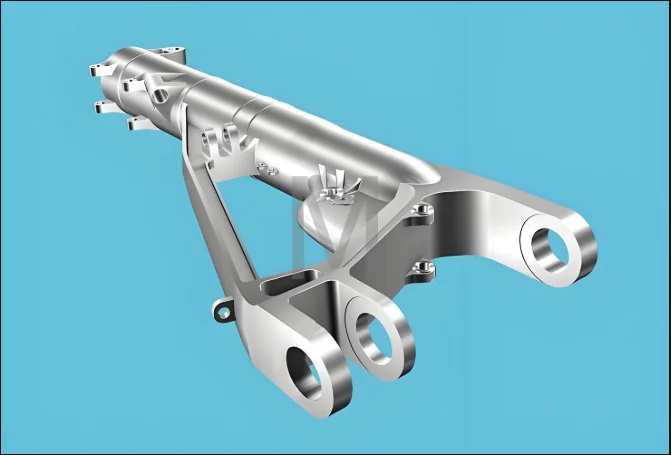

AM enables the creation of intricate structures that traditional machining can’t handle — honeycomb cores, closed cavities, non-circular curved pipes, and more. It supports function-structure integration by embedding functional materials directly into components.

4.2 Weight Optimization

Paired with structural optimization software, AM removes unnecessary material while maintaining strength and stiffness — reducing weight and boosting specific strength. This makes lightweight, high-performance landing gear feasible.

4.3 Customized, Agile Production

Traditional landing gear manufacturing demands expensive tooling and molds — impractical for small batches. AM eliminates this need, keeping costs consistent between single-piece and batch production. It also supports fully digital workflows, enabling rapid design iterations and shorter product development cycles.

5 Technical Challenges and Limitations

5.1 Ensuring Quality and Mechanical Stability

Temperature fluctuations during metal AM introduce residual stress, pores, and cracks, compromising part stability. Micro-forging and real-time defect detection can improve microstructures, but extensive multi-batch testing is still essential to ensure consistent performance.

5.2 Airworthiness Certification

Challenges include:

Incomplete standards

Limited certification for AM components and materials

Insufficient quality control systems

Long-term stability in harsh environments (e.g., high temperature, and pressure) still requires thorough verification and certification.

5.3 Scaling to Mass Production

AM excels in prototyping but faces slow production rates and high material costs — limiting large-scale manufacturing. Future improvements must boost production speed, cut material costs, and streamline cycle times to enable broader adoption.

5.4 Enhancing Design and Simulation Tools

Current simulation software struggles to predict multi-physics interactions (e.g., thermal gradients, stress, warpage) during AM. Further development of accurate simulation tools is crucial for defect prediction and process control.

6 Conclusion

Additive manufacturing holds immense potential for transforming aircraft landing gear production. It enables complex geometries, improves material efficiency, and accelerates development. However, challenges around quality stability, airworthiness certification, mass production, and design simulation remain.

With digitalization and intelligent manufacturing advancements, AM can evolve into an end-to-end optimized process. Real-time monitoring will enhance quality control, ensure compliance with aviation standards, and redefine the future of aerospace manufacturing.