Top universities in Machinery

- Stanford University

- University of California – Berkeley

- University of Michigan – Ann Arbor

- Harvard University

- University of Toronto

- Massachusetts Institute of Technology

- University of Pennsylvania

- Tsinghua University

Top CNC Machine Manufacturers

- Yamazaki Mazak

- Okuma Co., Ltd.

- Tsunezo Makino

- Mag

- Shenyang Machine Tool

- Dalian Machine Tool

- Qinchuan Machine Tool Group

Top CNC Services in the USA

- 3ERP

- ZETWERK Manufacturing USA Inc.

- Turner Bellows, Inc.

- Fairchild Auto-Mated Parts

- Source International

- Contract Machining & Manufacturing Co.

- Eagle Stainless Tube & Fabrication, Inc.

- Associated Fastening Products, Inc.

- Wyandotte Industries, Inc.

- Ardel Engineering & Manufacturing Co., Inc.

-

Geometric accuracy adjustment of CNC equipment

Restoring Precision: Practical Techniques for CNC Machine Alignment Modern machining often utilizes milling and turning machining centers due to their high efficiency. However, their complex designs make them prone to collisions. These collisions can cause significant geometric accuracy deviations, even misaligning the main and sub-spindle concentricity. We have gathered our experience and developed practical techniques…

-

Machining technology and fixture design for box parts

To enhance the quality of box products, reduce costs, and minimize waste, companies should thoroughly research and optimize box part processing technology. They must make smart decisions about production type, blank processing, positioning references, process combinations, and machining allowances to ensure precision. Additionally, designing practical, high-performance fixtures is vital. This requires strictly following design specifications…

-

Analysis of process parameters for machining thin-walled parts using CNC lathes

When we CNC machine thin-walled parts, their low rigidity makes them highly susceptible to deformation. Clamping, cutting forces, heat, and vibration all contribute to this, significantly impacting accuracy. Therefore, we must optimize process parameters—like fixture design, tool parameters, and cutting amounts—to ensure quality and precision. 1. Characteristics and Machining Challenges Thin-walled parts are common in…

-

Current status and prospects of steel powder development

Steel powder is a high-volume product extensively used in powder metallurgy. We use it not only in iron-based products but also widely in welding rods, soft magnetism, the chemical industry, metallurgy, food, and environmental protection. In recent years, major industrial countries worldwide have significantly focused on their research and development, continuously improving both production scale…

-

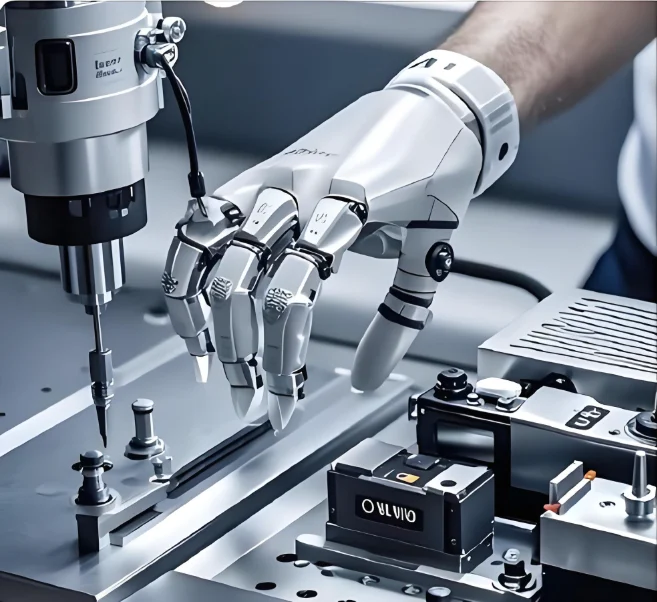

Research explores automation’s application in mechanical design and manufacturing.

The Transformative Power of Automation in China’s Mechanical Design and Manufacturing Automation technology is now a cornerstone of China’s mechanical design and manufacturing sector. Its continuous advancements have led to widespread adoption. This has fundamentally reshaped the industry’s landscape and driven significant progress. Automation integrates sophisticated control systems, precise sensor technology, and intelligent information processing.…

-

The Evolution and Modern Trends of Machine Tool Fixtures

1. How Machine Tool Fixtures Have Changed Machine tool fixtures have evolved through three key phases. Initially, they simply helped speed up manual work. In the second phase, fixtures became a crucial link between operators and machines. Their main job became positioning and securely holding workpieces. People increasingly realized that fixtures greatly affected operator productivity…

-

Discussion of laser treatment technology for injection mold surface

1. Introduction Injection molding depends heavily on injection molds. These molds play a vital role in the molding industry. They determine the final quality of molded products. By using them, manufacturers can achieve high precision, consistency, efficiency, and low material loss. These features help ensure structural integrity and dimensional accuracy. However, many molds have complex…

-

Application of Mechatronics CNC Technology in Mechanical Manufacturing

1 Application Value of Mechatronics CNC Technology in Mechanical Manufacturing 1.1 Enhancing Work Efficiency Mechatronics and CNC technology work together to improve the accuracy and efficiency of mechanical manufacturing. These technologies help operators control production parameters precisely. As a result, they improve coordination between different steps in the production process. This coordination increases the productivity…

-

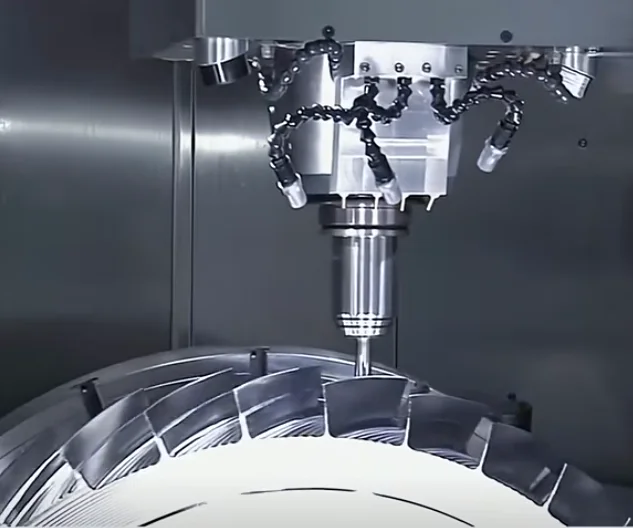

CNC manufacturing method for non-simple surfaces

1 Analysis of CNC Manufacturing Methods for Complex Surfaces Blower rotor blades and steam turbine blades have complex curved surfaces. These parts need high precision and surface quality. Multi-axis linkage envelope milling improves processing efficiency, surface finish, and accuracy. This method uses annular discs and cyclone cutters to achieve better results. The outer annular disc…

-

CNC Machining in Mold Manufacturing

Since CNC (Computer Numerical Control) machining technology emerged in the 1950s, engineers havedeveloped it from simple lathes into advanced multi-axis machine tools. This development has greatly enhanced machining capabilities. CNC technology reduces human error, improves precision, and ensures consistent quality. It plays a key role in raising the overall quality of mold manufacturing. 1 Basic…