The global automotive industry is growing rapidly. As a result, the demand for automotive parts manufacturing increases each year. Traditional machining methods cannot meet modern manufacturing needs. They are inefficient and lack precision. Numerical control (CNC) technology has revolutionized the machining method. It also improves the precision and efficiency of parts machining. This paper discusses the current status, design specifications, and future development strategies of CNC technology in automotive parts machining.

CNC technology

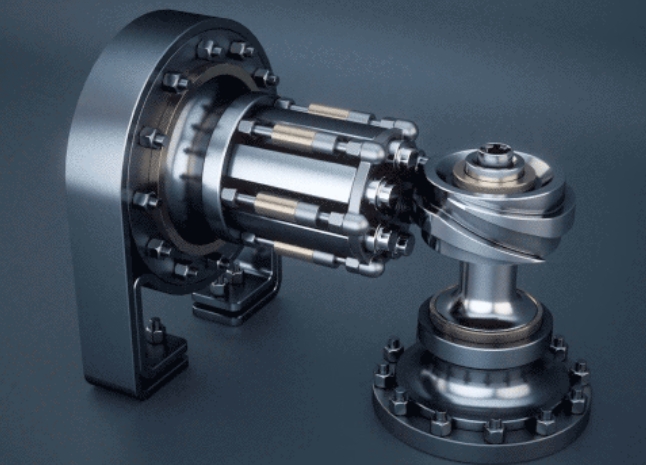

CNC technology, which stands for computer numerical control technology, controls machining equipment through a computer. It allows automated machining based on pre-programmed procedures. CNC machine tools accurately control the movement of tools and machining parameters. This ensures high-precision machining of complex parts.

Advantages

High precision allows CNC machine tools to achieve micron-level control accuracy. This ensures high precision and consistency in parts processing. High efficiency reduces human intervention by automating the process. As a result, productivity improves significantly. CNC machine tools process each part according to the program, ensuring consistency in mass production. These tools offer flexibility by easily handling parts of different shapes and materials. Automated programs further reduce operator intervention and minimize human error.

The integration of CNC technology in automotive parts machining

With the rapid development of the global automotive industry, the manufacturing demand for automotive parts is increasing year by year. Traditional machining methods cannot meet the needs of modern manufacturing because they are inefficient and lack precision. Numerical control (CNC) technology has revolutionized machining methods. It also improves the precision and efficiency of parts machining. This paper will discuss the current status, design specifications, and future development strategies of CNC technology in automotive parts machining.

Automotive parts machining design specifications

When machining automotive parts, you must follow certain design specifications to ensure smooth progress and stable machining quality. These specifications include material selection, machining process design, and setting machining parameters. You also need to consider the characteristics of CNC machine tools and machining capacity. Additionally, you should arrange the machining sequence and process path reasonably.

Application Strategies

1.Application of automated programming technology

Automated programming technology is able to quickly generate machining procedures for complex parts through the use of advanced CAD/CAM software. This not only greatly improves programming efficiency, but also reduces the error rate. For example, the import of 3D CAD models and automatic path generation make the programming of complex surfaces and geometric shapes easy and simple.

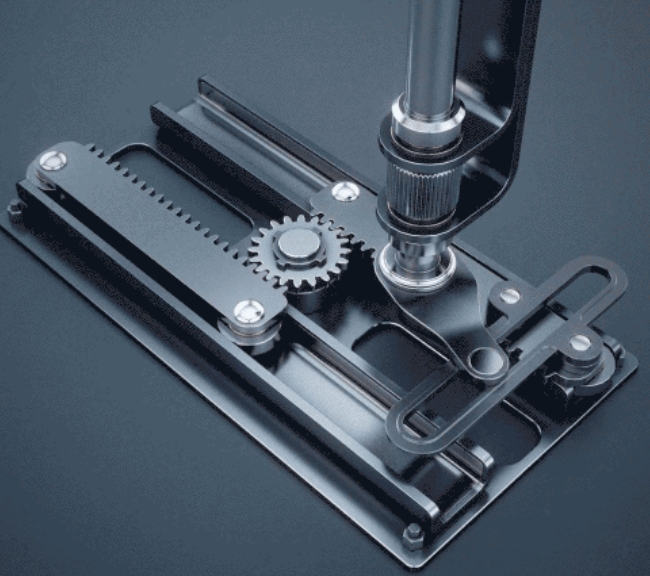

2.CNC transformation of the original machining equipment

Many traditional machining equipment through the CNC transformation, new vitality. These transformations not only reduce the cost of equipment renewal, but also improve the accuracy and efficiency of processing. For example, the manual lathe is transformed into a CNC lathe, which can achieve automated processing and mass production, and improve production efficiency.

3.Scientific application of intelligent technology and network technology

The application of intelligent technology and network technology makes CNC processing more intelligent and networked. For example, through the Internet of Things (IoT) technology, CNC machine tools are connected to the cloud to achieve remote monitoring and maintenance, which improves the utilisation rate and productivity of the equipment. At the same time, the application of intelligent sensors can monitor the processing status in real time, adjust the processing parameters in a timely manner, and ensure the processing quality.

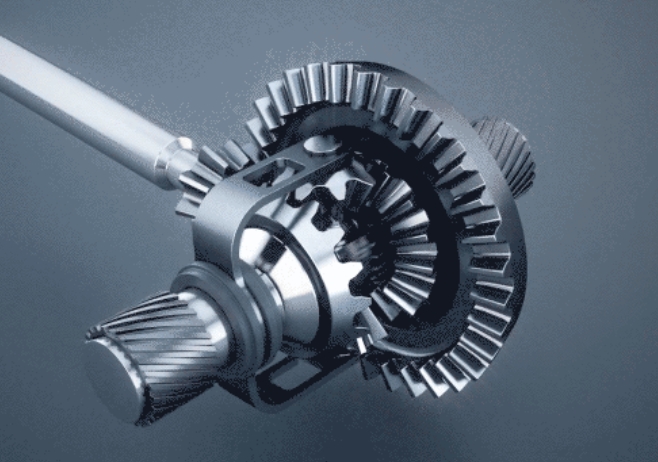

4.Improve the control of CNC technology

In order to meet the demand for high-precision parts processing, it is necessary to continuously improve the control of CNC technology. This includes optimising the control algorithm, improving the response speed of the servo system. For example, through the advanced servo control system, it is possible to achieve nano-level machining accuracy to meet the processing needs of high-end parts.

5.Scientific customisation and strengthening of intellectual property protection

According to specific processing needs, scientific customization of machining solutions ensures efficient and economical processing. At the same time, intellectual property protection is strengthened to safeguard the innovative achievements in numerical control technology. For example, patent protection and technical barriers help maintain the enterprise’s technological advantage and promote the sustainable development of automation technology.

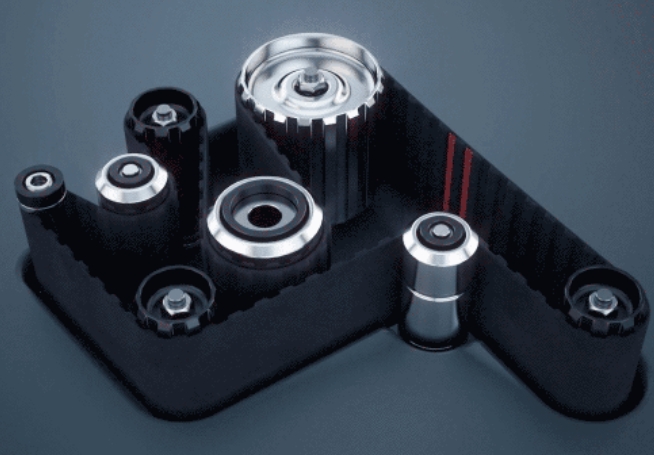

6.Develop a powerful platform with strong performance to effectively meet common and open demands

Developing CNC platforms with powerful performance can meet the needs of different users. These platforms not only have strong computing power and control accuracy, but are also compatible with different machining equipment and processes. For example, through open interfaces and modular design, the platform has good scalability and compatibility to meet different processing needs.

Grasping future application trends

CNC technology develops in line with the trend of intelligent manufacturing and industry. In the future, artificial intelligence, big data, and IoT technology will integrate more closely with CNC technology. This integration will drive further advancements in intelligence and automation. For example, big data analysis can optimize the machining process, which improves productivity and product quality. Artificial intelligence can enable autonomous programming and fault diagnosis, which enhances the equipment’s intelligence.

Conclusion

CNC technology plays a key role in automotive parts machining, providing strong technical support for the automotive industry. By applying science and fostering continuous innovation, CNC technology will improve processing efficiency and quality. This will drive the ongoing progress of automotive manufacturing. In the future, as intelligent manufacturing and the industry grow, CNC technology will have broader development prospects. It will support the high-quality development of the automotive industry.