With the continuous development of the manufacturing industry, rapid prototyping technology has become an important part of modern manufacturing. With its fast, efficient, and flexible characteristics, it provides unprecedented convenience for product development, prototype, ng, and small-batch production.

In actual rapid prototyping applications, quality control and inspection technology play a key role in ensuring product consistency and quality. This article will explore how effective quality control and inspection technology can ensure product consistency and quality in the rapid prototyping process. It will also discuss how to reduce the scrap rate.

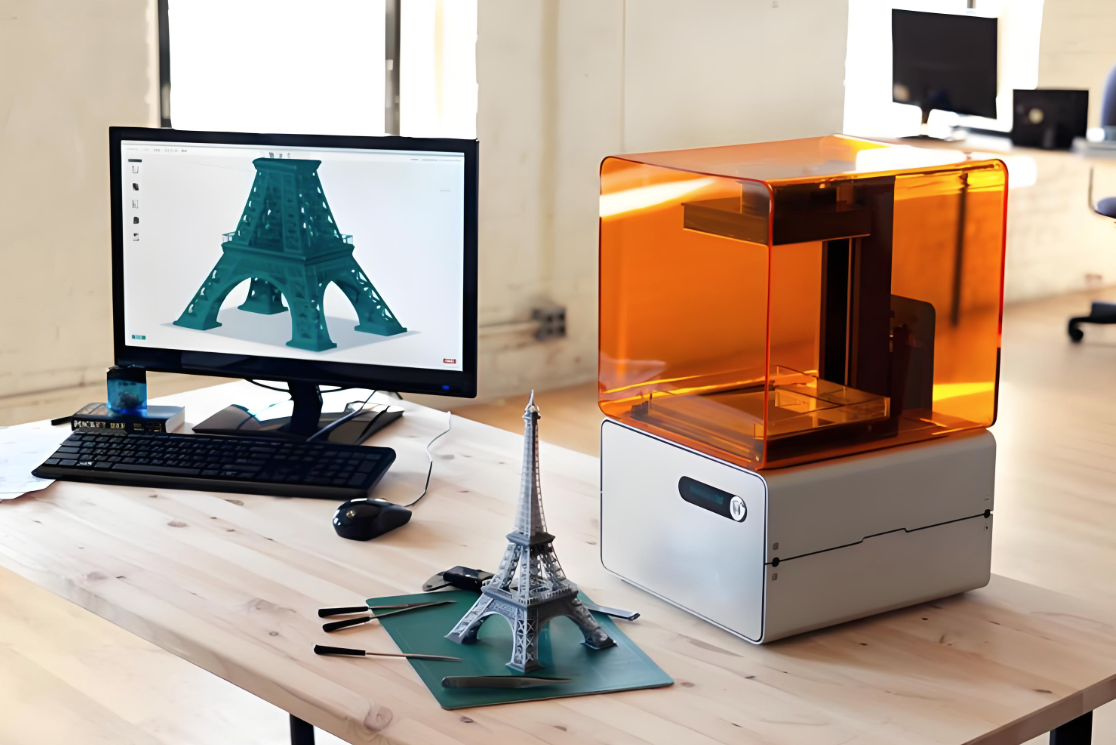

Overview of Rapid Prototyping Technology

Rapid prototyping technology manufactures physical products based on a three-dimensional CAD model by stacking materials layer by layer. Since its inception, industries like aerospace, medical, automotive, and consumer electronics have widely adopted it. The core advantage of rapid prototyping lies in its ability to quickly verify designs, shorten development cycles, and support the manufacture of complex geometric structures.

Although rapid prototyping offers many advantages, multiple factors affect the quality of the final product during actual production. Material properties, processing accuracy, and process parameters all play a role. Therefore, effectively controlling and detecting these factors is essential to ensure the quality of rapid prototyping products.

Quality control challenges in rapid prototyping

1. Uncertainty of materials

Many types of materials are used in rapid prototyping, including plastics, metals, and ceramics. These materials have different physical and mechanical properties. Fluctuations in material properties can cause quality problems during the rapid prototyping process. These problems include insufficient strength, dimensional deviation, and surface roughness. Therefore, selecting and controlling materials are the top priorities for ensuring quality.

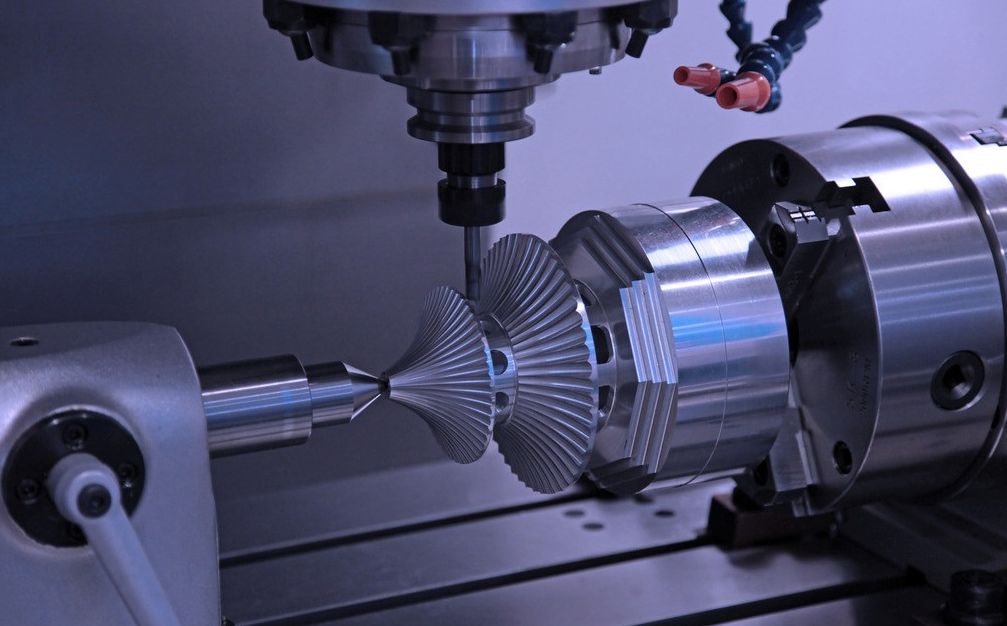

2. Complexity of process parameters

Rapid prototyping technology relies on precisely controlling multiple process parameters, such as laser power, scanning speed, and layer thickness. Different combinations of these parameters affect the product’s density, surface finish, and dimensional accuracy. The mutual influence between the parameters is complex and difficult to predict. Therefore, operators must carefully optimize and adjust the settings.

3. Influence of the production environment

External factors like temperature and humidity in the production environment and the equipment’s operating status affect the quality of rapid prototyping products. For example, during laser sintering, changes in ambient temperature can cause uneven melting of the material. This uneven melting affects the product’s density and strength.

4. Uncertainty of post-processing process

In the rapid prototyping process, post-processing steps like support removal, polishing, and heat treatment play a crucial role in determining the quality of the final product. Operators usually carry out these processes manually. It is hard to ensure consistency in each treatment. This inconsistency may cause fluctuations in the surface quality and dimensional accuracy of the product.

Methods and technologies for rapid prototyping quality control

To meet the quality challenges in rapid prototyping, modern manufacturing uses a series of quality control methods and technologies. These methods ensure the consistency and quality of products. They cover real-time monitoring during production and include detection and analysis after the product is completed.

1.Process monitoring and real-time feedback

Process monitoring is a key technology to ensure the quality of rapid prototyping. By monitoring key parameters such as temperature, pressure, and laser power in real-time during production, we can discover and correct potential quality problems promptly. For example, in selective laser sintering (SLS), a slight change in laser power can affect the sintering effect. We can make adjustments early through real-time monitoring and feedback mechanisms to prevent waste products from forming.

2.Intelligent algorithms and data analysis

Data analysis technology has developed, and intelligent algorithms are being applied more extensively in rapid prototyping quality control. Analyzing a large amount of production data helps establish a mathematical model that links product quality with process parameters. This model can predict and optimize the production process. For example, machine learning-based algorithms identify key parameters that affect product quality. These algorithms improve product consistency by optimizing the combinations of these parameters.

3.Automated testing and non-destructive testing technology

Automated testing technology plays an important role in rapid prototyping quality control. For example, the use of automated visual inspection systems can quickly detect product appearance defects and dimensional deviations. Non-destructive testing technologies, such as X-ray CT and ultrasonic testing, detect the internal structure of the product without destroying it. They help identify internal defects like cracks and pores.

4.Statistical process control (SPC)

Statistical process control is a method of ensuring product quality by monitoring variables in the production process. We collect data on key parameters during the production process. We use statistical tools, such as control charts, to analyze the data. This allows us to monitor the production status in real-time. We can identify any deviation from the normal range. We can then make timely adjustments to prevent the production of defective products.

5. Full-size detection and 3D scanning technology

Full-size detection and 3D scanning technology can be used for final quality inspection of rapid prototyping products. By comparing the produced products with the original CAD model, we can accurately measure the size and shape deviations. This ensures the products meet the design requirements. These technologies improve detection accuracy, reduce detection time, and boost production efficiency.

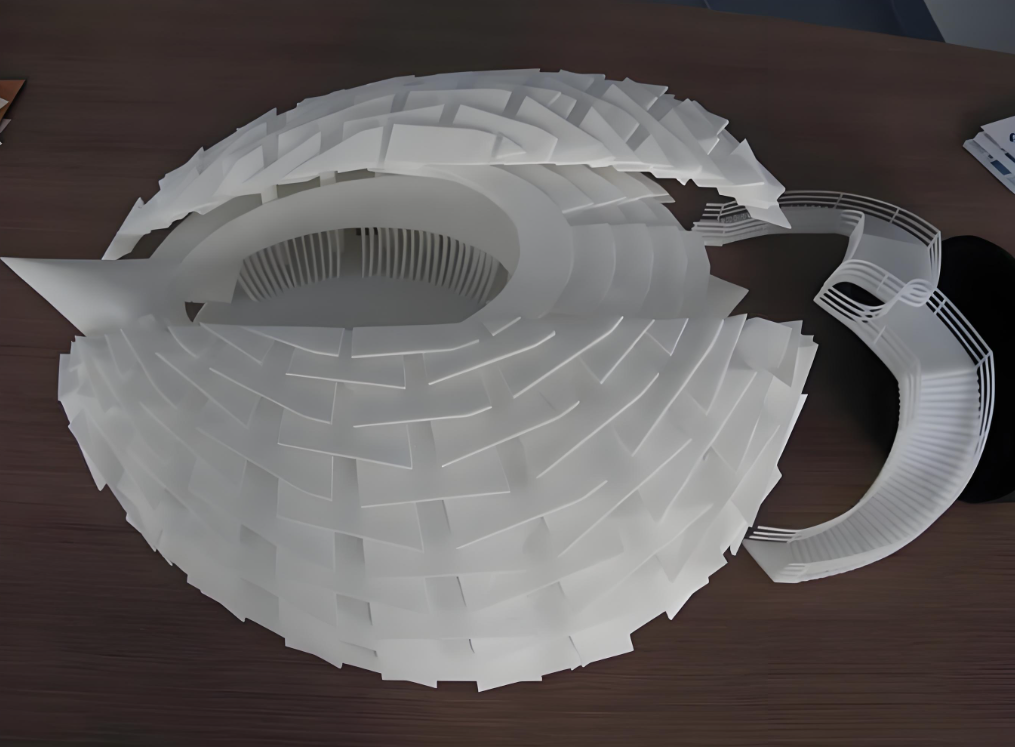

6.Virtual simulation and process optimization

Before rapid prototyping, virtual simulation technology simulates the entire production process. It predicts and optimizes the parameter settings for each process link, improving product consistency. Virtual simulation reduces trial and error costs and accelerates the development and application of new processes.

Strategies to reduce scrap rate

The scrap rate directly affects the production cost and competitiveness of the enterprise. In the process of rapid prototyping, the following strategies can be used to effectively reduce the scrap rate and improve production efficiency.

1.Process parameter optimization

Through experimental design and simulation analysis, the process parameter combination of rapid prototyping is optimized to find the optimal production conditions and reduce the generation of scrap caused by improper parameter settings.

2.Material management and control

Strictly control the quality of raw materials, including the composition, performant,ce, and storage conditions of the materials, to ensure the consistency and stability of the materials, thereby reducing quality defects caused by material problems.

3.Strengthen operator training

The technical level of operators directly affects the quality of rapid prototyping products. Through regular training and skill improvement, ensure that operators can master the operation and maintenance of equipment and reduce human operating errors.

4.Implement preventive maintenance

The stability of equipment has an important impact on product quality. Through regular preventive maintenance, ensure that the equipment is always in the best operating state and reduce waste caused by equipment failure.

5.Establish a comprehensive quality management system

Establish a comprehensive quality management system to ensure product quality in all aspects, from the warehousing inspection of raw materials, and monitoring of the production process to the final inspection of finished products. Through the PDCA cycle (plan, execute, check, and process), continuously improve the quality management process and reduce the scrap rate.

Future trends and prospects

With the advancement of Industry 4.0, the quality control of rapid prototyping technology will usher in new development opportunities and challenges. In the future, the in-depth application of technologies such as intelligent manufacturing, the Internet of Things, and big data analysis will bring more possibilities for the quality control of rapid prototyping.

1. Intelligent quality control system

The intelligent quality control system will be able to achieve real-time monitoring and adaptive adjustment of the entire production process. Through artificial intelligence technology, the system can automatically analyze production data, identify quality problems, make optimization suggestions, and even automatically adjust process parameters, thereby realizing the intelligence of the production process and the automation of quality control.

2. Closed-loop feedback control

Closed-loop feedback control systems will be more widely used in rapid prototyping. By combining detection data with process parameters to form a closed-loop control, dynamic adjustment of the production process can be achieved, thereby further improving product consistency and quality stability.

3 .Green manufacturing and sustainable development

Future rapid prototyping quality control will not only focus on product quality but also pay more attention to the environmental protection and sustainability of the production process. By optimizing the process flow, and reducing energy consumption and material waste, the goal of green manufacturing can be achieved.

4. Quality control combining virtual and reality

Virtual reality (VR) and augmented reality (AR) technologies will be used in rapid prototyping quality control. By combining virtual simulation with real production, operators can monitor and adjust the product inreal-timee to improve production accuracy and efficiency.

Conclusion

Quality control and detection technology play a key role in ensuring product consistency and quality in rapid prototyping. They also help reduce scrap rates and boost corporate competitiveness.

As technology advances and the manufacturing industry develops, quality control in rapid prototyping will become more intelligent, automated, and sustainable. This will support the transformation and upgrading of the manufacturing industry. In this process, manufacturing companies must explore new technologies and methods. They need to optimize production processes and improve product quality to stay competitive in the market.