In modern manufacturing, CNC machining and additive processes are two important processing technologies, each with unique advantages. However, CNC machining shows significant advantages in many aspects compared to additive processes. CNC machining is the top choice for many industries due to its precision, material variety, surface finish, and mass production efficiency. Especially in manufacturing environments that require high precision and consistency, CNC machining has shown its irreplaceable advantages.

What is CNC machining? Additive process?

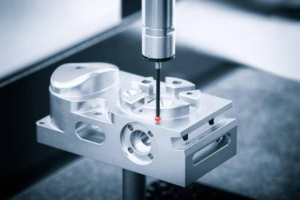

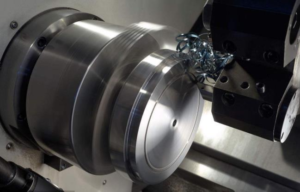

CNC processing (Computer Numerical Control) is an automated machining technology controlled by a computer. It uses computer programs to control machine tools for cutting, milling, drilling, and producing high-precision, complex parts in materials like metal, plastic, and wood.

Additive Manufacturing, also known as 3D printing, is a technology that creates three-dimensional objects by adding materials layer by layer. Unlike traditional subtractive machining, additive processes build objects by adding material instead of removing it.

Advantages

1. Processing accuracy and stability

CNC machining is known for its high precision and stability, especially when manufacturing complex parts. CNC machining removes material through cutting, milling, drilling, etc. to achieve precise geometry and dimensional control. Additive processes stack materials layer by layer, making them less precise and prone to errors, especially for fine details.

An aerospace company needs to manufacture a high-precision turbine blade with complex geometry and strict accuracy requirements. After comparison, the company chose CNC processing technology. CNC machine tools ensure precise, repeatable blade dimensions, while additive processes cannot match this precision.

2. Diversity of material selection

CNC machining is suitable for a variety of materials, including metals, plastics, wood, and composites, making it ideal for high-strength, high-durability applications. The material selection for additive processes is relatively limited, especially in the application of high-strength materials.

Case: A medical equipment manufacturer needs to produce a batch of high-strength, stainless steel casings that are corrosion-resistant and wear-resistant. Due to the limitations of additive technology in processing high-strength stainless steel, CNC processing was finally chosen. This ensures not only the strength and performance of the material but also the long service life of the housing.

3. Surface finish and post-processing requirements

CNC machining produces high-quality surface finishes directly, often without the need for complex post-processing steps. By using high-quality cutting tools and precise machining paths, CNC machines can achieve extremely smooth surfaces. This is critical for certain parts that require a high surface finish. The additive process usually produces a rougher surface, which requires additional post-processing such as grinding and polishing.

Case: An automotive parts supplier needed to produce an engine block that required smooth surfaces and tight tolerances. CNC machining directly achieves smooth surfaces, eliminating the need for post-processing and boosting efficiency while reducing costs.

4. Efficiency of mass production

CNC machining excels in mass production, especially when producing multiple parts of the same design. CNC machines are able to maintain consistent high precision and efficiency. Additive processes are best for low-volume or customized production, while CNC machining is more time- and cost-effective for high-volume production.

Case: An electronic product manufacturer needs to produce a batch of aluminum heat sinks. Each heat sink has the same design and requires high production efficiency and consistency. CNC machining allows the company to quickly produce consistent, high-quality heat sinks in large quantities. This high-volume production capability gives CNC machining a huge advantage in efficient production.

5. Ability to process complex geometric shapes

While additive processes are best known for their ability to create complex geometries, CNC machining still excels in certain situations. CNC machining can achieve high complexity and precision in parts with internal channels, complex curves, or precision structures through multi-axis linkage, while additive processes may struggle with the same level of complexity and accuracy.

Case: A pharmaceutical equipment manufacturer needs to produce a special mixer with a complex internal structure that contains multiple curved surfaces and precision channels. The company successfully manufactured this complex part through five-axis CNC machining, ensuring its efficiency and stability during the production process. However, additive processes have greater challenges in handling these precision channels.

6 . Processing speed cost-effectiveness

CNC machining generally has faster processing speeds, especially when processing metal materials. Additive processes are slow, especially for large parts, with high time costs. CNC machining usually has higher material utilization and simpler waste disposal, reducing production costs.

Case: An energy equipment company needs to produce a batch of large aluminum parts for wind power equipment. CNC machining is the optimal choice due to its speed, efficiency, and cost-effectiveness, reducing delivery time and production costs, and thus maintaining a market edge.

7. Production consistency and quality control

CNC machining excels in production consistency and quality control, especially in high-volume production. CNC machine tools are controlled by computers, and the production process of each part is completely consistent, ensuring product consistency. Due to the different ways of stacking materials in the additive process, there may be slight differences between different parts, affecting consistency.

Case: A consumer electronics manufacturer needs to produce the casing of a new smartwatch. Each casing is required to be exactly the same size and appearance to ensure a high-quality image of the product. Through CNC processing, they are able to produce parts with extremely high consistency without having to worry about differences between products, which greatly enhances the brand’s market competitiveness.

Conclusion

CNC machining offers advantages over additive processes in precision, material variety, surface finish, batch production efficiency, complex geometry handling, speed, cost-effectiveness, and consistent quality control. These advantages make CNC processing still occupy an important position in modern manufacturing. Especially in scenarios that require high-quality and high-efficiency production, CNC processing is still the technology of choice for many industries. CNC processing plays a crucial role in practical applications, offering manufacturers reliable technical support.