Sheet metal processing is an important manufacturing process, widely used in the fields of automobiles, aerospace, electronic equipment, household appliances, etc. Its basic process includes cutting, bending, stamping, welding, and other operations, and the effect of these operations depends largely on the selected metal materials. Different metal materials have different processing characteristics, which directly affect the performance, cost, and production efficiency of the final product. Common metal materials include carbon steel, stainless steel, aluminum alloy, and copper alloy.

Carbon steel

1. Basic characteristics of carbon steel

Carbon steel is a kind of steel containing carbon elements. It can be divided into low-carbon steel, medium-carbon steel, and high-carbon steel according to the carbon content. Low carbon steel generally has a carbon content of 0.05% to 0.25%, with good plasticity and weldability; medium carbon steel has a carbon content of 0.25% to 0.60%, with good strength and toughness; high carbon steel has a carbon content of more than 0.60%, with high hardness and wear resistance, but poor plasticity.

2. Processing characteristics of carbon steel

- Cutting: Low-carbon steel is easier to cut due to its good plasticity and low hardness. Laser cutting, stamping, and other methods can achieve good results. Medium carbon steel may require greater power and appropriate cutting speed to ensure cutting quality when cutting, while high carbon steel may require more professional cutting equipment and technology due to its high hardness.

- Bending: Low-carbon steel has excellent bending performance and can usually achieve bending operations at a smaller bending radius. The bending performance of medium carbon steel is relatively poor, requiring greater bending force and a larger bending radius. Due to its high hardness and brittleness, high-carbon steel cracks easily during the bending process, so it is important to adjust the process parameters carefully.

- Welding: Low-carbon steel exhibits excellent weldability and can be welded using various methods, such as arc welding and gas-shielded welding. Medium carbon steel performs well in welding but requires preheating and post-heat treatment to reduce welding stress and deformation. High-carbon steel proves difficult to weld and tends to crack during the process, requiring special welding materials and techniques.

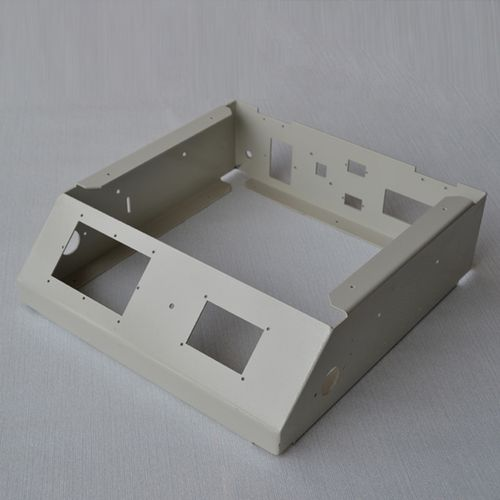

3. Application Examples

Carbon steel is widely used in the manufacture of structural parts, mechanical parts, construction steel, etc. For example, automobile body structural parts, bridge steel structures, etc. all use carbon steel as the main material.

Stainless steel

1. Basic characteristics of stainless steel

Stainless steel refers to steel containing at least 10.5% chromium and has excellent corrosion resistance. Stainless steel is mainly divided into austenitic, martensitic, and ferritic types according to its alloy composition. Austenitic stainless steel (such as 304, and 316) offers good corrosion resistance and plasticity, making it ideal for use in the food industry and medical devices. Martensitic stainless steel (such as 410, and 420) provides high hardness and wear resistance, making it suitable for knives and cutting tools. Ferritic stainless steel (such as 430) combines good corrosion resistance with magnetism but has lower strength.

2. Processing characteristics of stainless steel

- Cutting: Stainless steel is relatively difficult to cut, especially stainless steel with high alloy composition. Due to its high hardness and wear resistance, the cutting tool wears faster, requiring the use of high-quality tools and generating a large cutting power during the cutting process.

- Bending: Austenitic stainless steel bends well, but you should increase the bending radius appropriately to avoid material cracking. Ferritic stainless steel, on the other hand, has relatively poor bending performance and is prone to cracking, so you need to pay special attention to the bending process parameters.Martensitic stainless steel has poor bending performance and usually requires bending operations at high temperatures.

- Welding: Austenitic stainless steel welds well, and welders typically use argon arc welding or TIG welding. They must control the concentrations of nitrogen and oxygen during welding to prevent corrosion of the welded joints.Ferritic stainless steel has poor welding performance and requires the use of appropriate welding materials and techniques. Martensitic stainless steel is difficult to weld and usually requires subsequent heat treatment to eliminate welding stress.

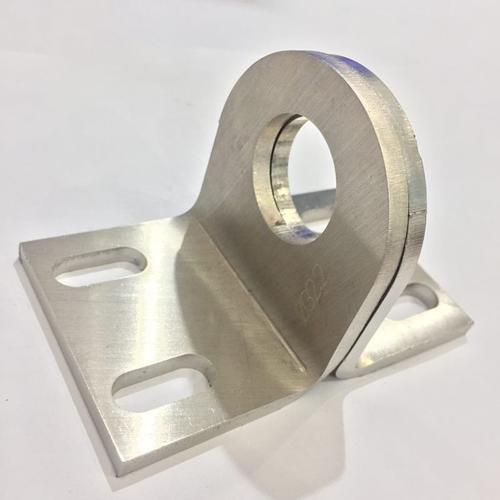

3. Application Examples

Industries such as food processing, medical equipment, and architectural decoration use stainless steel for its corrosion resistance and aesthetic qualities. For example, stainless steel kitchen equipment, chemical reactors, and building facades all use stainless steel as the main material.

Aluminum alloy

1. Basic characteristics of aluminum alloy

Aluminum alloy is created by adding other metal elements (such as copper, magnesium, silicon, manganese, etc.) to aluminum. People generally classify aluminum alloys into aluminum-copper alloys, aluminum-magnesium alloys, aluminum-silicon alloys, and others. Aluminum alloys offer excellent lightweight properties, corrosion resistance, and machinability, making them widely used in aerospace, automobile, construction, and other industries.

2. Processing characteristics of aluminum alloys

- Cutting: The cutting of aluminum alloys is relatively simple. Due to its softness and low hardness, manufacturers can use a variety of cutting tools such as saw blades and laser cutting. However, since aluminum alloys tend to generate cutting heat, they must adopt appropriate cooling measures.

- Bending: Aluminum alloys exhibit good bending performance, particularly aluminum-magnesium alloys, which can bend at a small radius. However, they experience significant elastic recovery, so controlling the bending angle and radius precisely is necessary to avoid springback.

- Welding: The welding of aluminum alloys requires the use of special welding methods, such as argon arc welding (TIG welding) or laser welding. Oxide layers are easily generated during welding, and proper treatment is required to ensure welding quality. When welding aluminum alloys, it is important to control the welding temperature and speed to avoid overheating and weld deformation.

3. Application Examples

Aluminum alloys are widely used in products with lightweight design requirements, such as aerospace parts, automobile bodies, and building curtain walls. For example, aircraft fuselage structural parts, automobile doors, and window frames are all made of aluminum alloys.

Copper alloy

1. Basic characteristics of copper alloy

Copper alloy is an alloy made of copper with other elements such as zinc, aluminum, and nickel added. Common copper alloys include brass (copper-zinc alloy), bronze (copper-tin alloy), and aluminum bronze (copper-aluminum alloy). Copper alloys have good electrical conductivity, thermal conductivity, and corrosion resistance, and are widely used in electrical, mechanical, and construction fields.

2. Processing characteristics of copper alloys

- Cutting: Copper alloys are easy to cut, and their high toughness and processability allow them to be processed with common cutting tools. However, the good thermal conductivity of copper alloys causes heat to build up during the cutting process, requiring proper control of cutting speed and cooling measures.

- Bending: Copper alloys have good bending performance and can be bent at a small bending radius. However, the good ductility of copper alloys makes spring back easy to occur during the bending process, requiring precise control of process parameters.

- Welding: Copper alloys weld well and typically use argon arc welding or arc welding. During the welding process, you should pay attention to the oxidation of copper and adopt appropriate welding materials and techniques to ensure the strength and stability of the welded joint.

Application Examples

Copper alloys are widely used in electrical connectors, mechanical parts, and architectural decoration. For example, copper alloy cable connectors, automotive engine parts, and architectural decoration accessories all use copper alloy materials.

Conclusion

The material selection in sheet metal processing has an important impact on the quality, performance, and cost of the final product. Carbon steel, stainless steel, aluminum alloy, and copper alloy each have different processing characteristics and are suitable for different application scenarios. Understanding the characteristics of these materials can help manufacturing engineers better select suitable materials, optimize processing technology, and improve production efficiency and product quality. In practical applications, we should comprehensively consider the performance, cost, and processing difficulty of the material based on specific needs and process requirements to select the most suitable sheet metal processing material.