A PCB CNC machine is a computer numerical control (CNC) system specifically designed to mechanically fabricate printed circuit boards (PCBs) by removing copper material from a copper-clad laminate according to digital design data. Unlike chemical etching, PCB CNC machines rely on precision milling, drilling, and routing processes to form circuit traces, pads, vias, and board outlines.

Definition and Core Concept

A PCB CNC machine converts electronic design files (typically Gerber and Excellon files) into toolpaths that guide rotating cutting tools. These tools selectively remove copper and substrate material to create the desired circuit pattern directly on the board.

In essence, it is a subtractive manufacturing method for PCB prototyping and low-volume production.

Main Functions of a PCB CNC Machine

A typical PCB CNC machine performs several key operations:

- Isolation Milling

Removes copper around traces and pads to electrically isolate them from surrounding copper areas. - Drilling

Creates precise holes for through-hole components, vias, and mounting holes. - Board Routing / Profiling

Cuts the PCB outline and separates individual boards from panels. - Engraving and Marking

Engraves reference text, symbols, or fiducials on the PCB surface.

Key Components

A PCB CNC machine generally consists of:

- High-speed spindle (typically 20,000–100,000 RPM) for fine copper milling

- Precision motion system (X, Y, Z axes with stepper or servo motors)

- Control electronics running CNC firmware or dedicated PCB software

- Workholding system (vacuum table or fixture plate)

- Tooling (micro end mills, engraving bits, drill bits)

Materials Processed

PCB CNC machines are commonly used on:

- FR-4 epoxy glass laminate

- FR-1 / phenolic boards

- CEM-1 / CEM-3 substrates

- Single-sided and double-sided copper-clad boards

They are not typically used for mass multilayer PCB production due to alignment and plating limitations.

Advantages of PCB CNC Machines

- No chemicals required (environmentally friendly)

- Fast turnaround for prototypes (same-day boards)

- Direct control over design changes

- Ideal for R&D labs, universities, and makerspaces

Limitations

- Limited trace width and spacing compared to industrial etching

- No built-in plated through-holes (manual or secondary process required)

- Not suitable for high-volume or fine-pitch multilayer PCBs

- Tool wear affects accuracy over time

Typical Applications

- Rapid PCB prototyping

- Proof-of-concept electronics

- Educational and research projects

- Small-batch, low-complexity boards

- In-house hardware development labs

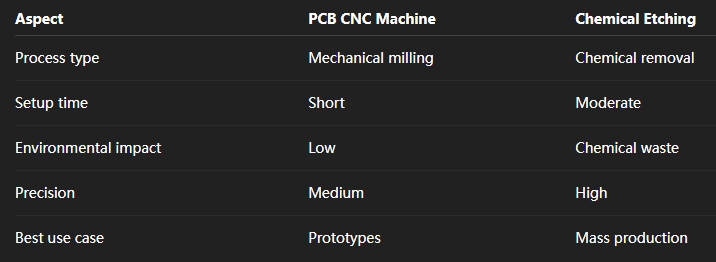

PCB CNC Machine vs Chemical Etching

Summary

A PCB CNC machine is a precision manufacturing tool that mechanically mills and drills copper-clad boards to produce functional PCBs without chemical processing. It is best suited for rapid prototyping and low-volume applications, offering speed, flexibility, and in-house control, while sacrificing some precision and scalability compared to traditional PCB fabrication methods.