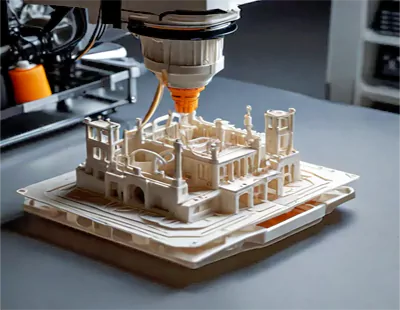

In today’s competitive market, the product development cycle often determines a company’s success. 3D printing rapid prototyping technology, with its high efficiency, precision, and flexibility, is quietly changing the traditional product development process.

This article explores how innovative technology accelerates product development, improves design verification and testing efficiency, and helps companies quickly respond to market needs and stay competitive.

Advantages of 3D printing rapid prototyping technology

1. Accelerate the development cycle

The traditional product development process involves design, prototyping, testing, and revisions, which is time-consuming. 3D printing rapid prototyping technology can directly convert design data into physical models, greatly shortening the development cycle. By rapidly producing prototypes, companies can quickly verify designs, test functionality, and resolve issues, accelerating product launches.

2. Reduce development costs

In the traditional manufacturing process, molds are usually required to make prototypes, which is expensive and has a long cycle. 3D printing eliminates the need for molds, directly printing complex shapes, reducing mold costs, and offering material flexibility to lower development expenses.

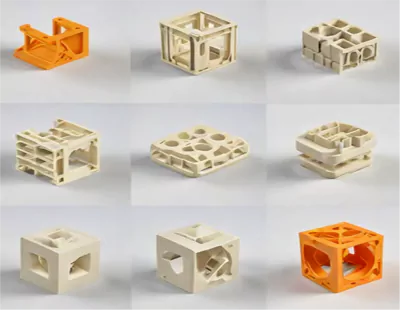

3. Improve design freedom

3D printing enables the creation of complex structures and fine details, allowing designers to fully explore creative and innovative designs, enhancing product innovation and market competitiveness.

How to apply 3D printing rapid prototyping to product development

1. Integrate into the design process

Enterprises should integrate 3D printing rapid prototyping technology into all aspects of product design, from concept design to functional testing to final product finalization. Through continuous iteration and optimization, ensure that the product can reach the optimal state in the design stage.

2. Strengthen teamwork

The application of 3D printing technology requires close cooperation among multiple departments such as design, engineering, and manufacturing. Enterprises should create a cross-departmental collaboration mechanism to ensure efficient information flow, and resource allocation, and promote product development.

3. Invest in advanced equipment

Choosing high-performance 3D printing equipment and high-quality materials is the key to ensuring the quality and efficiency of rapid prototyping. Enterprises should invest in advanced 3D printing equipment based on their needs and maintain and upgrade it regularly to ensure technological advancement and stability.

Successful Case Studies

Many well-known companies have successfully applied 3D printing rapid prototyping technology and achieved remarkable results. BMW has shortened new model development and improved quality and market response through 3D printing. Similarly, Apple uses 3D printing for product design and testing to stay ahead in the market.

Future Outlook

As 3D printing technology advances and costs decrease, more companies will benefit. Rapid prototyping will become a standard in product development, driving the manufacturing industry toward greater efficiency, flexibility, and intelligence. Companies should seize this opportunity to explore and apply 3D printing, enhancing their product development and market competitiveness.

Conclusion

As a revolutionary manufacturing method, 3D printing rapid prototyping technology is bringing unprecedented opportunities for product development. By accelerating the development cycle, reducing costs, and increasing design freedom, companies can quickly respond to market demands and maintain competitive advantages. Let us welcome this technological revolution together and create a better future.