3D cold printing technology is a new 3D printing technology that can print molded metal parts.

It is a low-viscosity, high solid-phase content of the metal slurry as the printing of the “ink” through the printer nozzle will be a metal slurry jet to the printing platform, while the chemical initiation, thermal initiation, and other ways to trigger the slurry in the polymerization of organic monomers, the formation of three-dimensional mesh structure will be in situ metal powder coating fixed, so that the metal slurry quickly cured! The metal slurry is solidified rapidly, realizing the printing of metal part blanks layer by layer.

The blanks are dried, degreased, and sintered to obtain dense metal parts.

The whole printing process is carried out at room temperature or low temperature (<100°C), so it is called “cold molding”.

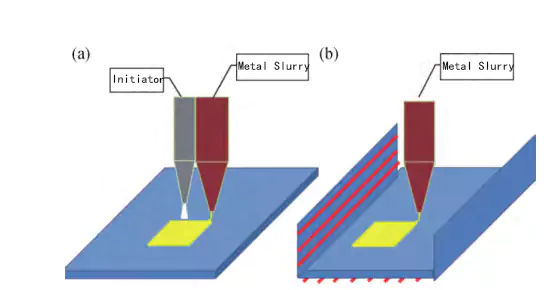

The principle of 3D cold printing technology, among other things, is that it uses two nozzles to alternately mix a metal slurry with a chemical initiator, which triggers in-situ curing of the slurry; and a heat source to cure the metal slurry.

The blanks are dried, degreased, and sintered to obtain dense metal parts.

The entire printing process is ongoing at room temperature or low temperature (<100°C), and is therefore called “cold molding”. 3D cold printing technology is based on the following principles: it uses two nozzles to alternately mix the metal slurry and the chemical initiator, which triggers in-situ solidification of the slurry; and curing the metal slurry by a heat source.

Technical Features

3D cold printing technology is built based on slurry casting technology and additive manufacturing theory by controlling the metal slurry layer by layer solidification, stacking, to mold metal parts blanks; its main process characteristics are as follows:

1) a wide range of raw materials

3D cold printing technology on raw materials powder has low requirements. Most metal and ceramic powder have developed a more mature slurry system and formulated slurry performance to meet the requirements of 3D cold printing technology. It can be more convenient in the slurry to add the required component powders, the use of metal and metal, metal and non-metal combination effect, the production of a variety of composite materials, and special performance materials.

Fig. 1 Schematic diagram of the principle of 3D cold printing technology: (a) chemical initiation; (b) thermal initiation

2) excellent molding ability

3D cold printing technology can be integrated into molding with any complex spatial structure of metal parts blanks by drying, degreasing, and sintering to produce dense metal parts.

3) High product accuracy

3D cold printing equipment printing accuracy can reach 0.1mm, printing and molding parts blanks with high dimensional and surface accuracy.

4) Low cost of wequipment

Cold printing process does not use high-energy beam-heating molten metal powder, so there is no need for high-energy beam-heating

Using a melting system and supporting a high-purity inert atmosphere or high-vacuum protection device greatly reduces equipment costs.

5)High production efficiency

By adjusting the initiating action, real-time solidify of the slurry can be realized, and the production cycle is short. The main part of the technology is only molding and sintering. The process is simple and easy to integrate without complicated follow-up processing. The technology is mature enough for industrial production, which is highly possible.

3D cold printing technology with low viscosity, high solid phase content of the metal slurry as the raw material for printing, printing molding parts blank composition uniformity, high density, high dimensional accuracy, and surface accuracy; in the drying, degreasing, and sintering process, the blank shrinkage uniformity, high density of sintering, not easy to crack, warp and deformation defects such as good performance of the product. 3D cold printing technology breaks through the limitations of the traditional manufacturing process in terms of shape and the limited choice of materials available for ordinary metal 3D printing technology. It can produce parts of great complexity with high efficiencies and integration.

3D Cold Printing Metal Matrix Composites

Metal matrix composites (metal matrix composites, referred to as MMC) is a composite material with metal or alloy as the matrix and particles or fibers of different materials as the reinforcing phase. Most of the metal matrix composites have a common point: the reinforcing phase distribution is relatively uniform. However, there are some metal matrix composites with unique distribution of reinforcing phase, such as raw material hybrid composites and structural hybrid composites. This paper’s GT35 steel-junction hard alloy impeller and YG8 hard alloy angle milling cutter are fabricated by 3D cold printing technology. The concept of simultaneous printing of structural hybrid composites using 3D cold printing technology is proposed.

GT35 sintered carbide closed impeller

AutoCAD software established a three-dimensional model of the closed impeller. The three-dimensional linear dimensions of the closed impeller model were enlarged by 118% (sintering shrinkage ratio of 18%). The impeller model was processed by layered slicing and then the data were transferred to the 3D cold printing equipment.

Fig. 2 Three-dimensional model of closed impeller

The organic monomer acrylamide (AM), cross-linking agent N, N′-methylenebisacrylamide (MBAM) was dissolved in deionized water at an appropriate concentration to make a premixed solution of organic monomer AM with a mass fraction of 20%; the dispersant ammonia was added to the premixed solution and mixed with the appropriate amount of GT35 steel-jointed carbide powder, and ball milled under N2 atmosphere for 12 h to produce a solid-phase content (volume fraction) of 57% solid phase content (v/v) of the suspension slurry, and the slurry was degassed.

Another way is to transport the GT35 steel-jointed hard alloy slurry into the 3D cold printing equipment, the main printer nozzle according to the cross-sectional shape of the slurry, continuously and quantitatively sprayed onto the printing platform while controlling the auxiliary nozzle to spray a certain amount of catalyst N,N,N′,N′-tetramethylethylenediamine and the initiator of the mixture of ammonium persulfate liquid. The metal slurry sprayed onto the printing platform was fully cured within 20s, and the layers were stacked until the entire closed impeller blank was fully formed. The thickness of the printed layer was 0.1 mm, and the printing speed was 70 mm/s.

The mechanical properties specimen blanks were printed with the same GT35 hard alloy slurry and printing parameters, and the GT35 hard alloy closed impeller blanks, and the mechanical properties specimen blanks were dried under vacuum at 120°C for 2h. Subsequently, they were degreased in a vacuum oven at 400°C for 2h, and then degassed in a vacuum oven at 800°C, 1000°C, and 1100°C for 1h each. Holding 1h exhaust, and finally rise to the sintering temperature of 1420 ℃ holding 1h. Test sintered state GT35 steel junction hard alloy mechanical properties of the specimen density, hardness and fracture strength, and other properties.

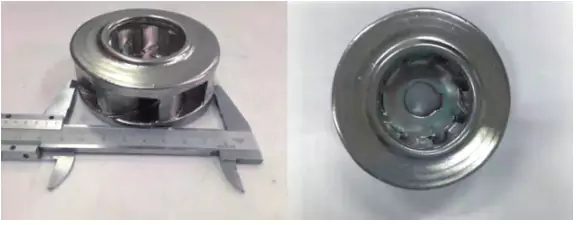

Figure 3 shows a GT35 steel-bonded carbide closed impeller made using 3D cold printing technology. 3D cold printing molding when the printing layer thickness is 0.1mm, so the closed impeller billet has high dimensional and surface accuracy. The billet shrinks uniformly during the sintering process. The whole closed impeller has a smooth surface except for a slight unevenness at the blade joint, and the shape, size, and structure satisfy the purpose of the design.

Figure 3 GT35 steel-jointed carbide closed impeller

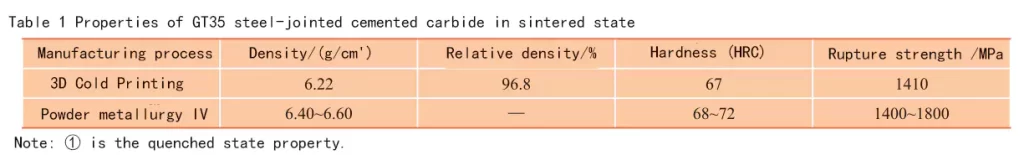

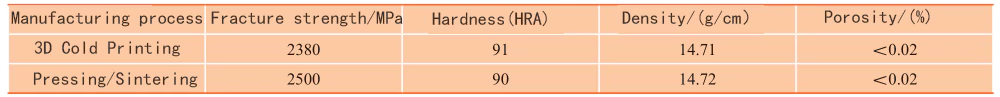

Table 1 shows the properties of GT35 steel-jointed hard alloy in the sintered state. It also lists the properties of GT35 steel-jointed hard alloy fabricated by the traditional powder metallurgy process. A comparison shows that the mechanical properties of GT35 steel junction hard alloy molded by 3D cold printing are similar to those of powder metallurgy products.

Table 1 Properties of GT35 steel-jointed carbide in sintered state

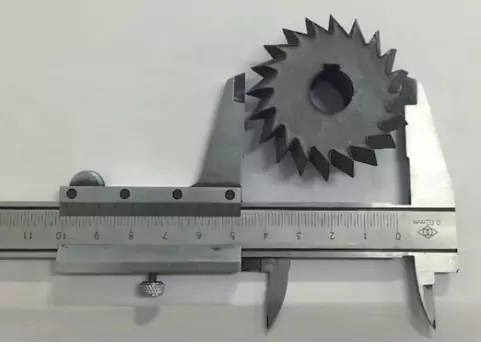

YG8 carbide angle milling cutter

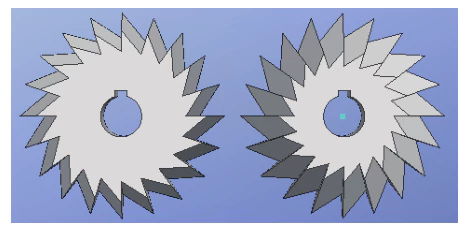

ProE Wildfi re 5.0 was used to establish a 3D model of the hard alloy angle milling cutter shown in Fig. 4. The 3D linear dimension of the angle milling cutter model was enlarged by 120% (sintering shrinkage ratio of 20%). The angle milling cutter model was processed by layered slicing and the data were transmitted to the 3D cold-printing equipment.

Figure 4 Angle milling cutter 3D model

Mix the solvent toluene with the organic monomer hydroxyethyl methacrylate (HEMA) in the ratio of 1:1 by volume, add the cross-linking agent N,N′-methylene bisacrylamide with a mass fraction of 0.05% and the catalyst dimethylaniline with a mass fraction of 0.03%, and dissolve and mix them well to make a pre-mixed solution with a volume fraction of 50% of the organic monomer (HEMA). An appropriate amount of YG8 hard alloy powder was added and stirred homogeneously.

In order to control its viscosity below 1 Pa-s, the YG8 powder in the slurry was dispersed using the hyperdispersant Solsperse-6000 to reduce the viscosity of the slurry and improve its fluidity. Then, the YG8 hard alloy suspension slurry with 58% of the solid phase content (v/v) was obtained by ball milling for 10h in an N2 atmosphere and subjected to vacuum degassing treatment.

The YG8 hard alloy angle milling cutter blanks were printed by 3D cold printing equipment with a layer thickness of 0.2 mm and a printing speed of 90 mm/s. The temperature of the whole printing chamber was 60°C during the printing process, so that the curing reaction of the slurry could be fully carried out within 30 s.

With the same YG8 hard alloy paste and printing parameters, the mechanical properties specimen blanks were printed. The angle milling cutter blanks and mechanical properties specimen blanks were placed in a vacuum drying oven and vacuum dried at 80°C for 6h.

Subsequently, they were degreased in a vacuum environment at 400°C for 2h, and the degreased blanks were sintered at 1400°C for 1h. The mechanical properties of the specimens were tested to detect the sintered YG8 hard alloy properties.

It is also a sintered YG8 carbide angle milling cutter. The sintered finished product has uniform shrinkage, high dimensional accuracy, clear angles, and no obvious defects.

Table 2 shows the properties of YG8 hard alloy produced in this experiment. It can be seen that its properties are close to those of the traditional pressed sintered process products.

Fig. 5 3D cold-printed YG8 carbide angle milling cutter

Table 2 Comparison of the properties of 3D cold-printed YG8 alloy with those of the conventional process

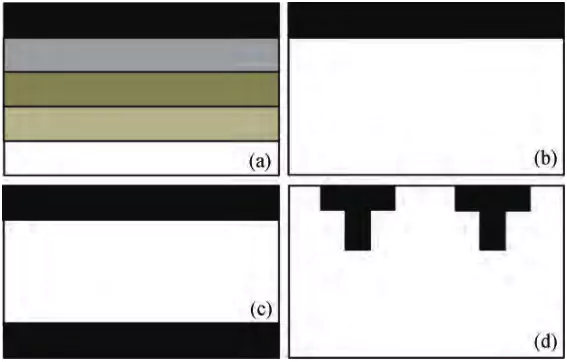

Structural hybrid composites

Hybridization is an effective and economical way to obtain high-performance composite materials because it can take into account the characteristics of two or more composite materials so that they complement each other, thus expanding the degree of freedom of material design.

By adding different kinds of reinforcing phases in the metal slurry, the mixing of raw materials can be easily achieved. Drawing on the principle of multi-nozzle color printing, multiple nozzles alternately spraying different compositions and contents of the metal slurry can synchronously print the structure of hybrid composites.

Similarly, 3D cold printing technology can integrate molding alternating lamination, single-sided lamination, double-sided lamination and surface inserts, and other structural hybrids.

The 3D cold printing technology is also capable of integrally molding composites composed of one or more combinations of alternating laminations, single-sided laminations, double-sided laminations, and surface inlays, as shown in Fig. 6.

Fig. 6 Structural hybrid composites: (a) alternating lamination; (b) single sided lamination (c) double sided lamination; (d) surface inlays

Conclusion

In this paper, the GT35 steel hard alloy closed impeller, and YG8 carbide angle milling cutter are fabricated by 3D cold printing technology; their shape, size, and structure satisfy the design purpose and requirements, and their performance is similar to that of similar products made by powder metallurgy. The density of GT35 steel-junction hard alloy in the sintered state is 6.22g/cm3, the hardness value is HRC67, and the fracture strength is 1410MPa; the density of YG8 hard alloy is 14.71g/cm3, the hardness reaches HRA91, and the fracture strength is 2380MPa.

By controlling multiple nozzles of the cold printing equipment to print different metal slurries in synchronized combinations, 3D cold printing technology provides a highly feasible, efficient, and low-cost process for integrating macro-structural hybrid composites.

3D cold printing technology will use low viscosity, high solid phase content metal slurry as the raw material for printing. It is applicable to all particle-reinforced and short fiber-reinforced metal matrix composites. The product shape has no limitations, so the mass production of more metal matrix composite material-shaped parts will become a reality.

To be precise, 3D cold printing technology can be applied to a wide range of raw materials, strong molding capacity, high product precision, low equipment cost, high production efficiency, easy system integration, and a high possibility of putting into industrialized production. Evaluated by Beijing International High-Tech Center, the technology is considered to have great investment value after maturation, and has already possessed the conditions for commercial development.