The Transformative Power of Automation in China’s Mechanical Design and Manufacturing

Automation technology is now a cornerstone of China’s mechanical design and manufacturing sector. Its continuous advancements have led to widespread adoption. This has fundamentally reshaped the industry’s landscape and driven significant progress. Automation integrates sophisticated control systems, precise sensor technology, and intelligent information processing. This integration empowers mechanical equipment to operate intelligently and automatically. This not only boosts production efficiency but also elevates product quality and reliability. Therefore, it is very important to thoroughly explore how automation is applied in mechanical design and manufacturing.

1 Key Advantages of Automation Technology

1.1 Enhanced Production Efficiency and Cost Reduction:

Automation dramatically improves production efficiency. It also lowers costs in mechanical design and manufacturing. The introduction of automated equipment and systems enables continuous production flows. These flows are uninterrupted. This minimizes downtime. It also reduces waiting periods associated with manual operations. This significantly shortens production cycles. It also maximizes output within a given timeframe. A prime example is the widespread use of CNC machine tools in mechanical processing. Digital systems control these advanced machines. They deliver precise and efficient production in metal and component processing. This leads to higher efficiency. It also results in reduced expenses. Pre-programmed instructions guide CNC machine tools. They automate machining processes. They precisely control manufacturing steps. This minimizes human intervention. It also reduces errors. Ultimately, this enhances both processing accuracy and overall production efficiency.

1.2 Superior Product Quality and Consistency:

Automation systems guarantee the accuracy of product processing. They also ensure the uniformity of product processing. This effectively minimizes human errors. It enhances product quality. It also strengthens brand competitiveness. The automotive manufacturing industry provides a compelling illustration. This is through the application of machine vision technology. This technology ensures the quality of machined parts. It also ensures the accuracy of assembly processes. For instance, in car body welding, machine vision systems conduct real-time weld inspection. They precisely identify flaws and deviations. They provide immediate feedback for adjustments. This ensures adherence to quality standards. Furthermore, in component assembly, machine vision enables automated part positioning. It also enables automated assembly. This is through image recognition and data analysis. This prevents human errors. It also improves assembly precision and consistency. Such automated assembly systems ensure that every component is correctly assembled. This follows standard procedures. This leads to enhanced overall product quality and reliability.

2 Applications of Automation Technology

2.1 Virtualization Technology:

Virtualization technology creates virtual environments. These environments simulate mechanical processes. This enables prediction. It also enables optimization. Remote control is also possible. During product design, virtual simulation allows engineers to analyze performance. They can refine designs. They can also reduce R&D costs. This is by minimizing the need for physical prototypes. It also reduces extensive testing. In the production phase, virtualization can simulate production line operations. It can identify inefficiencies in layout and workflow. It can also optimize processes for improved efficiency. For example, electronics manufacturers can leverage virtual production simulations. This helps them strategically plan component transport. It also helps in equipment synchronization. This prevents bottlenecks and delays.

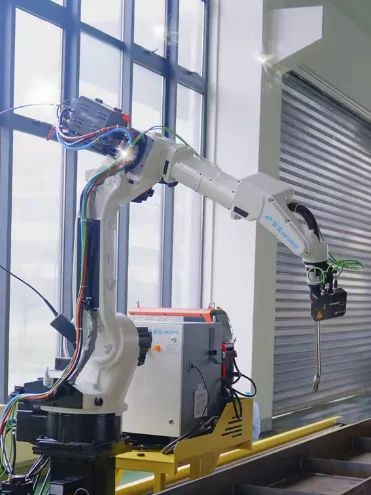

2.2 Intelligent Robot CNC Technology:

Intelligent robot CNC technology fuses artificial intelligence, CNC, and robotics. This significantly elevates the production efficiency of mechanical manufacturing. It also improves the product precision. In sectors like automotive parts manufacturing, these robots can operate continuously. They execute intricate tasks with remarkable accuracy. They can also dynamically adjust processing parameters in real-time. This is based on high-precision sensor feedback. This ensures micron-level precision. It also ensures exceptional consistency in the final products. The same applies to aircraft engine blade manufacturing.

2.3 Flexible Manufacturing Systems (FMS):

Flexible Manufacturing Systems (FMS) are built upon CNC technology. They integrate various other technologies. FMS offers the agility to adapt production processes. It can also adapt parameters. This accommodates diverse product types. It also suits small production runs. An FMS typically comprises processing systems. These include CNC machines and machining centers. It also includes logistics systems. These are AGVs, conveyors, and automated warehouses. Control systems are also part of FMS. These are computer hardware and software. They enable precise scheduling and management. Mechanical parts manufacturers, for instance, can utilize FMS. This allows them to rapidly switch machining programs. They can also change tools and fixtures. This enables them to produce a variety of parts on the same line. This happens without significant equipment changes. This not only boosts production efficiency. It also lowers production costs. It also accelerates product delivery times.

3 Case Study: Automotive Engine Manufacturing Company

An automotive manufacturing company has extensively integrated automation technology into its engine production line. They did this to enhance efficiency. They also wanted to ensure product quality. Reducing production costs was another goal. They have achieved high levels of efficiency. They also have high precision and intelligence in engine manufacturing. This is due to the introduction of automation technology.

3.1 Virtualization Technology in Engine Development:

The company uses virtual technology. They virtually assemble the engine. They simulate the assembly process on the computer. This allows engineers to check the matching accuracy. They also check the assembly sequence. This proactive approach helps them identify design problems. It also helps in finding manufacturing issues early. They can then optimize the process. They also utilize virtual testing. This simulates the engine’s operation under different working conditions. They analyze performance. They also analyze reliability. This enables design optimization. It also reduces the cost of actual testing. For example, they simulate the combustion process virtually. This provides valuable data for improving the engine’s design.

3.2 Flexible Automated Production Line:

The engine production line features flexible automation. It combines processing units. These units have CNC machines and robots. It also includes automated logistics systems. Examples are AGVs and conveyors. This setup allows for the mixed-line production of different engine models. It also enables the automatic transportation of parts.

3.3 Robotics in Welding and Assembly:

Automated welding robots perform precise welds on various parts of the car body. They use pre-set programs. They also use sensors to adjust parameters in real-time. This ensures high welding quality. It also ensures accuracy. For example, they avoid manual defects in the welding of engine cylinder blocks and cylinder heads. In engine assembly, robots also efficiently handle tasks. These include grasping, moving, and assembling parts. Examples are pistons and connecting rods. This guarantees assembly quality and reliability.

4 Conclusion: Embracing Automation

In today’s dynamic environment, the widespread adoption of automation technology has fundamentally reshaped the mechanical design and manufacturing industry. It does more than enhance efficiency and quality. It also drives the evolution of intelligent manufacturing. Personalized customization is another outcome. To thrive amidst global competition, companies must proactively embrace automation technologies. They also need to master them. This will help them achieve flexible production. It will also enable rapid responsiveness. Furthermore, investing in the research of advanced automation systems is crucial. The same applies to their application. This will help improve resource utilization. It will also mitigate operational risks. This will pave the way for future success in the mechanical design and manufacturing landscape.