Water jet cutting technology, as an important cutting process in modern manufacturing, brings significant advantages and opportunities to various industries. Its unique working principles and application characteristics make it the preferred choice for many enterprises in their production processes. This article will delve into the advantages of water jet-cutting technology and how it plays a crucial role in different fields, providing readers with a comprehensive understanding and insights.

What is Water Jet Cutting?

Water jet cutting is a technology that uses high-pressure water or a mixture of water and abrasive materials to cut materials. By pressurizing water to extremely high levels (typically over 60000 psi) and then releasing it through tiny nozzles, a high-speed water jet is formed, capable of cutting various materials. This technology is widely used in many industries due to its precision and versatility.

How Does Water Jet Cutting Work?

The principle of water jet cutting involves pressurizing water with a high-pressure pump and releasing it through small orifices. When the high-speed water jet contacts the material surface, the material is rapidly eroded and cut. For harder materials, abrasive materials such as garnet are often added to enhance cutting capabilities. The abrasive, when mixed with the water jet, effectively cut metals, ceramics, and composites.

Key Components of Water Jet Cutting

1. High-Pressure Pump

The high-pressure pump is the core component of water jet cutting, responsible for pressurizing water to the required high pressure, typically between 40000 psi and 90000 psi. This high-pressure water jet enables efficient and precise cutting.

2. Abrasive Delivery System

For applications requiring the cutting of harder materials, the abrasive delivery system mixes abrasive material (such as garnet) with the high-pressure water jet. Abrasives enhance cutting capabilities for materials like metals, ceramics, and glass.

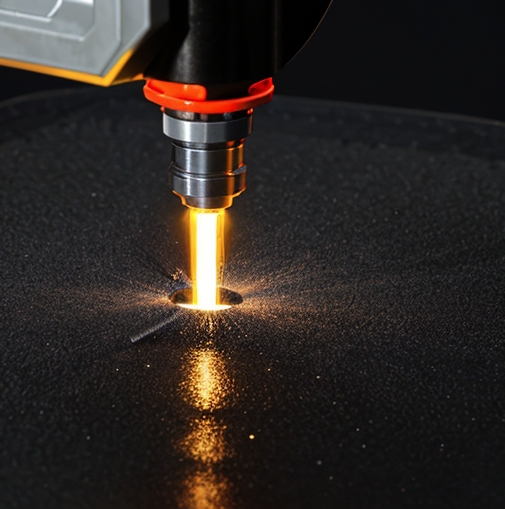

3. Cutting Head

The cutting head is where the water jet is released. It typically contains a small orifice through which high-pressure water or a mixture of water and abrasive is jetted out to achieve precise cutting.

4. Motion Control Equipment

Motion control equipment is used to manipulate the cutting head’s movement, ensuring precise cutting paths. Often controlled by Computer Numerical Control (CNC) systems, it can achieve complex shape cutting accurately.

5. Catch Tank with Cutting Bed

The cutting bed provides a support platform for the material, while the catch tank collects water and debris generated during the cutting process, preventing contamination and allowing for water recycling.

6. Control Software

Control software acts as the “brain” of the water jet cutting system, managing operations of the high-pressure pump, motion equipment, and cutting head for precise cutting. Modern control software offers path optimization and automation features, enhancing cutting efficiency.

Types of Water Jet Cutting Machines

1. Pure Water Jet Cutting Machine

This type of machine uses only high-pressure water and is suitable for cutting softer materials such as rubber, plastics, and food.

2. Abrasive Water Jet Cutting Machine

This machine mixes abrasive with the high-pressure water jet and is suitable for cutting harder materials like metals, stone, and glass.

Materials Suitable for Water Jet Cutting

Water jet cutting can handle a wide range of materials including, but not limited to:

– Metals (steel, aluminum, titanium, etc.)

– Glass and ceramics

– Stone (granite, marble, etc.)

– Plastics and composites

– Rubber and foam

– Food (meat, bread, etc.)

Advantages of Water Jet Cutting

– No Heat-Affected Zone

Water jet cutting is a cold-cutting process, avoiding heat deformation and changes in material properties.

– High Precision

Water jet cutting achieves high precision and fine-edge finishes, suitable for applications requiring intricate cutting.

– Versatility

Capable of cutting almost all types of materials, from soft rubber to hard metals and fragile glass.

– Environmentally Friendly

Uses water and natural abrasives, environmentally friendly with no harmful gas or smoke emissions.

Industrial Cutting Applications of Water Jet and Its Products

Water jet cutting is widely used in industries such as:

– Aerospace

Cutting high-strength metals and composite parts.

– Automotive Manufacturing

Cutting metal, plastic, and composite components.

– Building and Stonework

Cutting stone and glass.

– Food Processing

Cutting food products such as meat and bread.

– Electronics

Cutting circuit boards and precision parts.

Comparison with Other Cutting Technologies

– Laser Cutting

Laser cutting is suitable for high precision and thin materials but may not perform well on thick and reflective materials, and it can generate a heat-affected zone.

– Plasma Cutting

Plasma cutting is suitable for cutting thick metals but with lower precision and also generates a heat-affected zone.

– Mechanical Cutting

Mechanical cutting using saws or blades is suitable for simple shapes and high-volume production but is less effective for complex shapes and hard materials.

Conclusion

Water jet cutting technology, with its high precision, no heat-affected zone, versatility, and environmental friendliness, has become an indispensable means of processing in modern industries. Whether cutting soft rubber, hard metals, or fragile glass, water jet cutting efficiently and accurately completes tasks across various industries. By selecting the appropriate type of water jet cutting machine and optimizing cutting processes, businesses can significantly improve production efficiency and product quality.