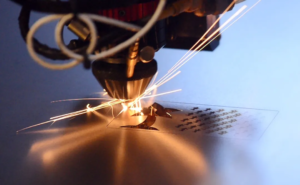

Laser cutting is an efficient and precise processing technology widely used in various industrial fields. It uses a high-energy laser beam to irradiate the surface of the material, causing the material to melt, vaporize or reach the ignition point quickly, and at the same time blows away the melted or burning material with a high-speed airflow, thereby achieving cutting.

Types of parts suitable for laser cutting

1.Metal materials

Laser cutting is very suitable for the processing of metal materials, which is one of its main application areas. Common metal materials include stainless steel, carbon steel, aluminum alloy and titanium alloy. Metal materials have a high absorption rate of laser beams, so high-quality cutting effects can be obtained.

The advantages of laser cutting metal materials are: fast speed, high precision and small heat-affected zone. These advantages make laser cutting widely used in automobile manufacturing, machinery manufacturing and aerospace.

2.Non-metallic materials

Although non-metallic materials have a low absorption rate for laser beams, high-quality cutting can be achieved by adjusting parameters such as laser power, cutting speed and gas pressure. Common non-metallic materials include: wood, plastic, glass, and ceramics.

Laser cutting of non-metallic materials has the advantages of fast speed, smooth cuts, and no need for secondary processing. It is widely used in furniture manufacturing, architectural decoration, and electronic products.

3.Complex shapes and tiny parts

Laser cutting, with its high precision and high speed, can easily cut out various complex shapes and tiny parts. These parts may be difficult to achieve with other processing methods, but laser cutting can easily cope with them. For example, in the fields of microelectronics and biomedicine, laser cutting can be used to manufacture tiny devices and parts.Limitations

Limitations

Although laser cutting has many advantages, it also has some limitations. For example, for some high-reflectivity materials (such as copper, gold, etc.), laser cutting is more difficult and requires special processes and equipment. In addition, laser cutting also has limitations on the thickness of the material and is generally suitable for thinner materials. Therefore, when choosing laser cutting, it is necessary to evaluate and select according to the specific material and processing requirements.

Conclusion

Laser cutting is suitable for processing many types of parts, including metal materials, non-metal materials, complex shapes and tiny parts. It has the advantages of high precision, high speed and high efficiency, and is widely used in various industrial fields. When choosing laser cutting, it is necessary to evaluate according to the specific processing requirements and material properties to obtain the best processing effect. With the continuous development of technology, the application scope of laser cutting will be further expanded and optimized.