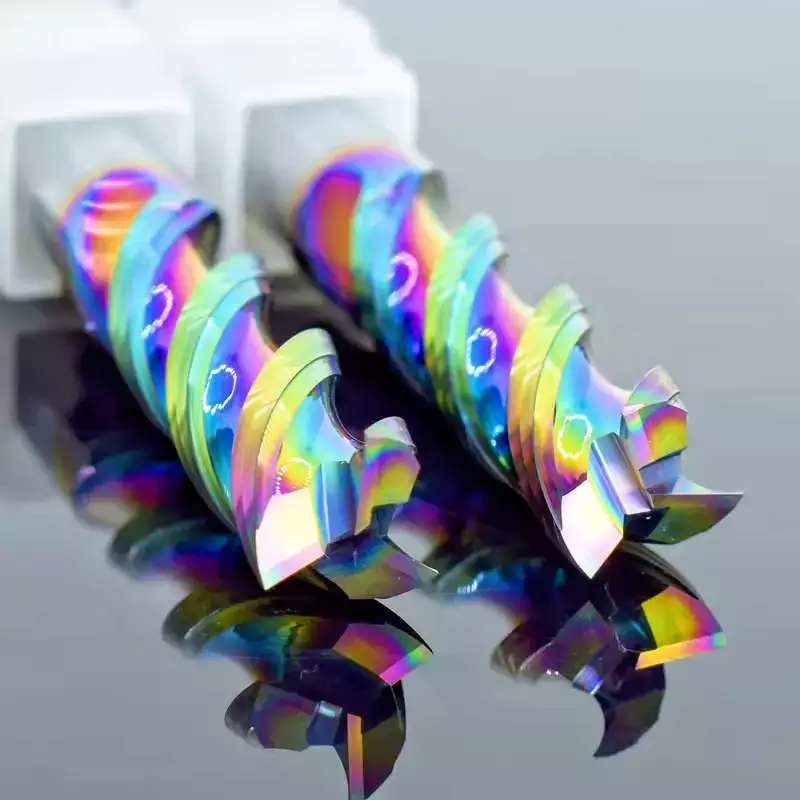

How do you choose tools during CNC machining?

Choosing the right tools for CNC machining is crucial for achieving high-quality products. Here are some factors to consider when selecting tools for CNC machining: Material Compatibility: Choose cutting tools that are specifically designed for the material you are machining. Different materials (such as aluminum, steel, plastics, etc.) require different tool geometries, coatings, and cutting…

The significance of high-speed milling from an academic point of view

Physical modeling and simulation of high-speed cutting process and cutting parameter optimization on this basis is the most effective way to solve the low efficiency of CNC machine tool machining. Process physical modeling and simulation refers to the cutting process for the physical quantities (such as chip thickness, cutting force, power, torque, cutting temperature, surface…

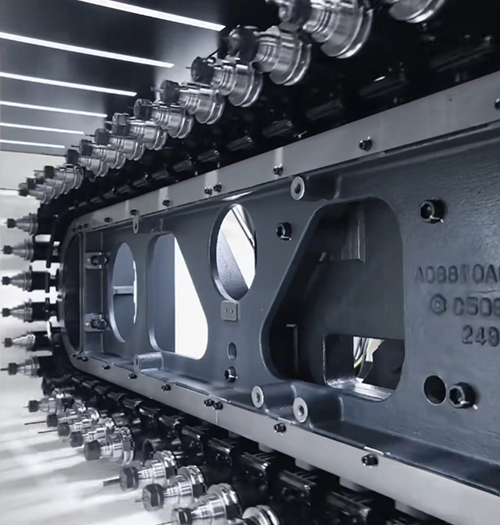

CNC Machine Automatic Tool Changers

Within machining, an Automatic Tool Changer (ATC) is an invaluable addition to Computerized Numerical Control (CNC) machine tools. Its primary function is to enhance both production efficiency and the tool-carrying capacity of the machine. ATCs facilitate rapid tool changes, minimizing unproductive downtime. Typically, these systems are employed to bolster a machine’s capacity for utilizing various…

CNC machine tool turning quality control method

CNC machine tool turning technology is a production and processing technology based on digital technology and intelligent terminals. This technology can achieve high-precision control of CNC production in the processing and production of parts, ensuring that the results of processing and production have high quality and acceptance rate [1]. With the continuous development of the…