Analysis and optimization of CNC machine tool machining accuracy

The key indicator for evaluating the performance of CNC machine tools is machining accuracy. CNC machine tools can guarantee machining accuracy within a certain range, but long-term and frequent use of CNC machine tools will cause them to be unable to maintain their original high accuracy. Therefore, it is very important to improve the machining…

Real-time measure technical in CNC machining

Measurement technology is usually based on the machine tool and the use of measurement tools such as tool setting probes, machine probes, 3D software, and so on. In the machining of the workpiece, to take the appropriate means to measure the specific geometric characteristics of the machine tool, and on this basis, according to the…

Analysis of CNC machining technology for shaped threads

Profiled thread is a kind of thread with special shape, whose shape and size are different from ordinary thread. Special CNC machining technology is required for the machining of profile threads to meet the special shape and size requirements. This paper will introduce the CNC machining technology of shaped threads, including its characteristics, classification and…

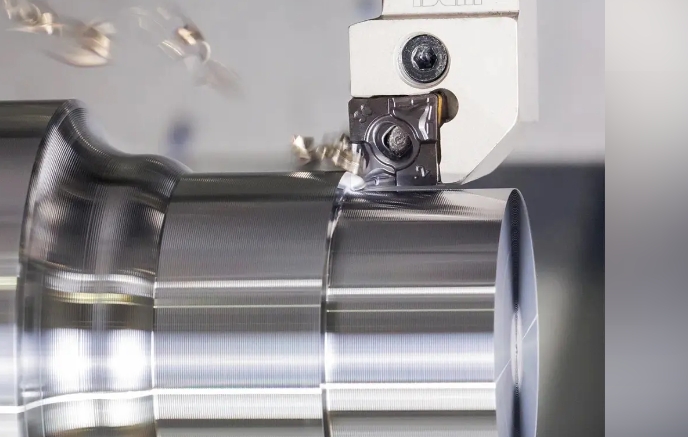

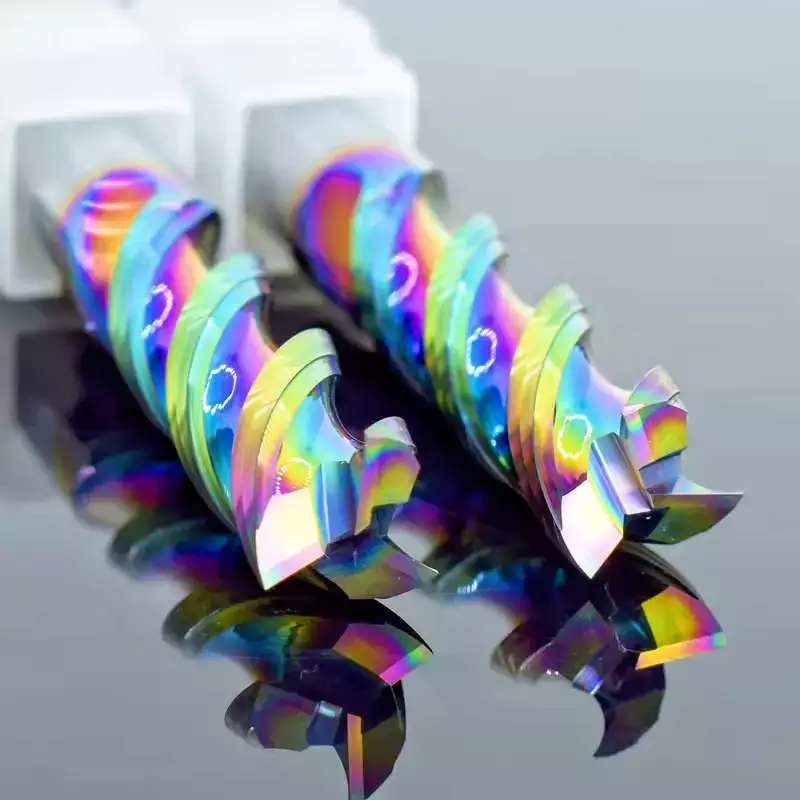

Research and development of high-speed cutting technology

Cutting processing is currently more widely used in the field of mechanical manufacturing processing methods [1], to improve the efficiency of cutting processing, reduce production costs, to promote the economy has important practical significance. With the popularization and development of CNC automation technology, the auxiliary time of workpiece processing is greatly reduced, corresponding to the…

Analysis of CNC machining technology of special-shaped threads

Currently, profile threads are mainly used in production machinery for plastics, rubber and puffed food. This is mainly because the profile thread has the characteristics of high speed, accuracy and stability, which is the important foundation of industrial production [1]. In the basic equipment of the plastics and rubber industries, the profile thread screw is…

The significance of high-speed milling from an academic point of view

Physical modeling and simulation of high-speed cutting process and cutting parameter optimization on this basis is the most effective way to solve the low efficiency of CNC machine tool machining. Process physical modeling and simulation refers to the cutting process for the physical quantities (such as chip thickness, cutting force, power, torque, cutting temperature, surface…